RFID reader module: MFRC522

So, hello to all viewers and welcome back to Gettobyte Platform. In This blog you are going to know about RFID Reader MFRC522, which is designed by NXP Semiconductors. Objective would be to interface this module with Host MCU’s like of NXP Semiconductors, STMicroelectronics or other vendors MCU’s. Will make the driver to interface the RFID Reader with any MCU, not unlike just with Arduino and Arduino IDE environment. To make the driver of RFID reader at first, we need to dig into its datasheet, to understand its various sub parts. And that’s all about this blog is gotten going to be, to make the datasheet understand in easy way-out.

Table of Contents

Next & Previous Blog

RFID Technology

RFID modules is a wireless sensing technology which is used to track/identify/monitor the objects.

MFRC522 RFID Reader/PCD

MFRC522 is a highly integrated reader/writer IC for contactless communication at 13.56 MHz. These reader supports the ISO 14443 A protocol for communicating with RFID Tags. They are used to detect the MIFRAME RFID tags.

MFRC522 has internal RF transceiver, which provides a robust and efficient implementation for demodulating and decoding signals from MIFRAME compatible cards using ISO 14443 A protocol. The digital module of MFRC522 manages the complete ISO/IEC 14443 A framing and error detection (parity and CRC) functionality.

MFRC522 supports 3 tags of MIFRAME family, that are MF1xxS20, MF1xxS70 and MF1S50 products.

MFRC522 features

MFRC522 though quite old RFID reader and in today’s time many new advance RFID readers have come up. But so as to get started with this technology as a hobbyist/student/DIY project, it is perfect module to lay your hands on this Technology.

- MFRC522 has highly integrated analog circuitry to demodulate and decode responses when RFID tags are brought in close proximity of these devices.

- RFID readers are connected with some host MCU, where the processing of data which is received via RFID tags happens according to the application. MFRC522 can connect with host MCU, using SPI, Serial UART and I2C -bus interface.

- It supports ISO 14443 A protocol and can be used with MIFRAME family of RFID tags. And in MIFRAME family it supports only MF1xxS20, MF1xxS70 and MF1xxS50 products.

- It has internal CRC-coprocessor.

- Internal FIFO buffer which can handle 64 bytes of sending and receiving.

- It uses the Crypto-1 cipher for authenticating.

- It supports Internal oscillator for connection to 27.12 MHz quartz crytsal.

- It is low power device, need 2.5 V to 3.3 V power supply.

- It also has flexible interrupt modes when some RFID tags are detected and trigering events too. In addition to flexible interrupt, it has programmabe I/O pins and timer.

- It can perform Internal self-test too.

MFRC522 Functional description

MFRC522 Host Interfaces

MFRC522 can be connected to Host MCU using 3 serial protocols: UART, I2C or SPI.

MFRC522 checks the current host interface type.

automatically after performing a power-on or hard reset. The MFRC522 IC identifies the host

interface by sensing the logic levels on the below pins after the reset phase.

The MFRC522 is equipped with a series of registers that allow the Host MCU to access its functional description blocks. To ensure the proper functioning of the MFRC522, the Host MCU must initialize and configure these functional blocks by sending the corresponding register addresses.

Each register is essentially an address byte that is transmitted from the Host MCU. Depending on the function described in the register section, read/write operations are performed on the corresponding address byte.

It is crucial to properly initialize and configure these functional blocks to ensure the optimal performance of the MFRC522. By understanding the purpose of each register and its corresponding function, the Host MCU can effectively communicate with the MFRC522 and achieve the desired results.

–> MFRC522_write_register()

–> MFRC522_Read_register()

MFRC522 Interrupts

MFRC522 can trigger the interrupts, when certain events occur. There are 8 events as shown in below table when interrupt can be triggered.

When above event occurs, IRQ pin is used to interrupt the host. IRQ pin signal is asserted and host MCU can use its interrupt handling capabilities (basically NVIC if we are talking about ARM based MCU) on what to do when corresponding interrupt has occurred.

- Status1Reg Register IRq bit is used to indicate if any interrupt source has been triggerered.

- Which interrupt has been triggered is indicated by ComIrqReg and DivIrqReg Register.

- Which interrupts to be configured and behavior of IRQ pin is configured by ComIEReg and DivIEReg Register.

MFRC522 Time Unit

There is a Timer unit in MFRC522, that is used for multiple purposes. Timer unit is essential for maintaing the configuring the clock and analog interfaces. Also timer unit can be used for following features:

- Timeout counter

- Watchdog counter

- Stopwatch

- Programmable one shot

- Periodical trigger

Timer has an input clock of 13.56 MHz derived from the 27.12 MHz quartz crystal oscillator. The timer consists of 2 stages: prescaler and counter.

- The prescaler(TPrescaler) is a 12-bit counter. That can be configured using TModeReg register’s TPrescaler_Hi[3:0] and TPrescalerReg register’s TPrescaler[7:0] bits.

- The Reload value for the counter is defined by 16 bits between 0 & 65535 in the TReloadReg register.

- The current value of the timer is indicated in the TCounterVAlReg Register.

MFRC522 FIFO

FIFO overview

The MFRC522 contains an internal FIFO buffer of 64 bytes, which is equivalent to 8 x 64 bits. This buffer is utilized for both input and output data streams. The host MCU has the capability to perform both Read and Write operations on this FIFO. The host MCU sends commands to PCD for communication with PICC. these commands are specified in ISO14443 A standard, which is then inputted into the FIFO. When the PICC responds to these commands, the response is also stored in the FIFO. The host MCU can then read the FIFO to obtain the response from the PICC.

The FIFO buffer is a crucial component in the communication process between the host MCU and the PICC. It allows for efficient data transfer and ensures that all responses are stored in a centralized location. The ability to perform both Read and Write operations on the FIFO provides flexibility and control to the host MCU. By utilizing the FIFO buffer, the communication process is streamlined and optimized for maximum efficiency.

About FIFO registers

FIFO buffer input and output data bus is connected to the FIFODataReg register. Writing to this register stores one byte in the FIFO buffer and increments the internal FIFO buffer write pointer. Reading from this register shows the FIFO buffer contents stored in FIFO read pointer and decrements the FIFO buffer read pointer.

Only one FIFO buffer has been implemented which can be used for input and output. The microcontroller must

ensure that there is not any unintentional FIFO buffer accesses.

The FIFOLevelReg is utilized to determine the number of bytes stored in the FIFO. This register is particularly useful in checking the number of bytes received in the FIFO buffer when the PICC sends a response to the PCD command. By using the FIFOLevelReg, you can easily keep track of the amount of data stored in the FIFO, which is essential in ensuring the smooth operation of your system.

One can also get the status of FIFO buffer using status and error registers.

- FIFO buffer almost full warning can be got to know from Status1Reg register’s HiAlert bit.

- FIFO buffer almost empty warning can be got to know from Status1Reg register’s LoAlert bit.

- FIFO buffer overflow warning, using ErrorReg register’s BufferOvfl bit.

MFRC522 CRC

MFRC522 has a Cyclic Rebudency Check (CRC) coprocessor to check the integrity of the data when data from PICC is received or when data is wriiten to PICC.

- CRC has preset value 0000h, 6363h, A671h or FFFFh. We can configure the preset values using ModeReg CRCPreset[1:0].

- CRC polynomial for the 16-bit CRC is fixed to x^16 + x^12 + x^5 + 1.

- CRCResultReg register indicates the result of the CRC calculation.

- CRC algorithm which is used is according to ISO/IEC 14443 A and ITU-T.

To perform the CRC calculation refer its state machine in below section.

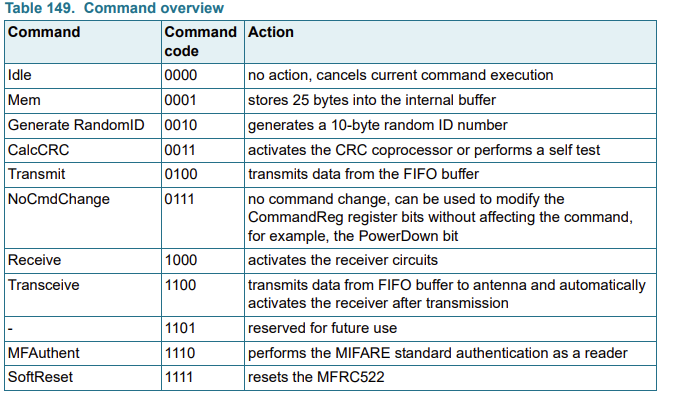

MFRC522 Command Set

MFRC522 operation is determined by certain commands. According to these commands, correspondingly MFRC522 would be performing some action.

So, it’s like at first, we will configure the FIFO, CRC, Interrupts and timer unit. After that Host MCU will instruct the commands to MFRC522 in order to tell what it has to do. Host MCU will write the command code to the CommandReg Register.

Main commands that would be used are Idle, Transceive, CalcCRC and Transmit commands. Transceive command is the one which has to be sent from Host MCU to MFRC522 to send the FIFO buffer data to the antenna, which is further propagated to the RFID readers. And according to the data which we have written in FIFO RFID readers would act and give response.

Each command that needs a data bit stream (or data byte stream) as an input immediately processes any data in the FIFO buffer. An exception to this rule is the

Transceive command. Using this command, transmission is started with the BitFramingReg register’s StartSend bit.

MFRC522 Block Diagram

Above is the simplified block diagram of MFRC522 module. MFRC522 has an internal memory, power supply, interrupt pins, FIFO buffer, Antenna and analog interface, digital module for communicating with Host MCU.

Analog Interface handles the modulation and demodulation of the analog signals. FIFO Buffer ensures fast and convenient data transfer.

Register bank are the set of registers through which MFRC522 would be configured and initialized to use. Parameters like Clock, Interrupts, status of errors while communicating with RFID readers, CRC calculation, FIFO configuration and etc need to be configured before using the MFRC522.

How the MFRC522 Internal system works?

Host MCU will send PCD Commands to MFRC522, according to which it will perform some operations. MCU will send these commands by writing into one of the registers of PCD.( For MFRC522 CommandReg is register)

Operations like:

- Activation of CRC Coprocessor

- Transmission of data from FIFO buffer of MFRC522 and activation of receiver circuits to get the response from PICC

- transfer of data from FIFO to an internal buffer

- soft reset and authentication-based operations

Further MFRC522 will emit the commands for communicating with PICC, here referred to as PICC Commands, according to which operation with PICC takes place, like scanning of PICC, selecting the PICC, reading and writing the data on PICC. MFRC522 emits these commands via electromagnetic induction and electric coupling. ( That is the main working principle behind the RFID technology)

Host MCU to PCD

Host MCU will send the commands to PCD, according to which PCD will perform the operations like activation of FIFO buffer or CRC coprocessor, and transmission of data from FIFO. We will name these commands as MFRC522 Commands sets. Host MCU will send those commands to PCD (here MFRC522) by writing into the CommandReg Register using low level Host Interface write API.

- Idle Command: Places the MFRC522 in Idle mode.

- Mem Command: Transfers the 25 bytes from the FIFO Buffer to the internal buffer. This command is used when, we want to read the data from PICC( As described in ISO-14443-4 doc), as PICC response is always recorded in PCD FIFO.

- Generate RandomID: generates a 10-byte random ID number.

- CalcCRC: Activates the CRC coprocessor or performs a self test.

- Transmit: transmit data from the FIFO buffer

- NoCmdChange: no command change, can be used to modify the CommandRef register bits without affecting the command

- Receive: activates the receiver circuits

- Transceive: Transmit data from the FIFO buffer to antenna and automatically activates the receiver after transmission.

- MFAuthent: performs the MIFARE standard authentication as a reader

- SoftReset: This command performs a reset of the device. The configuration data of the internal buffer remains unchanged. All registers are set to the reset values. This command automatically terminates when finished.

PCD to PICC

Further there are also command set which PCD have to emit to communicate with PICC and enter the PICC into some state machine.

PICC States:

- Power-off State: In the POWER-OFF state, the PICC is not powered by a PCD operating field

- Idle State: In the IDLE state, the PICC is powered. It listens for commands and shall recognize REQA and WUPA commands.

- Ready State: Cascade levels are handled inside this state to get the complete UID. PICC enters the ACTIVE state when it is selected with its complete UID.

- Active State: PICC complies with ISO-14443-4 to accept protocol activation commands (RATS)

- HALT State: In this state PICC only responds to WUPA command.

- Protocol State: PICC behaves according to 1s014443-4 specifications.

We will name these commands as PICC commands. Host MCU will write these PICC command into the PCD FIFO (refer the MFRC522 FIFO section on how to write the data on FIFO). PCD would transmit the FIFO data when it enters the Transceiver state machine (refer above topic).

PCD would transmit these commands via the electromagnetic induction and communicates with PICC via electronic coupling. PCD’s have RF transceivers through which it emits the electromagnetic waves with commands sets encoded in them. PICC have antenna and small circuitry, which gets energized via electromagnetic waves emitted by PCD and then further both PCD and PICC get coupled together to have 2 way wireless communication. How PCD would send commands to PICC and in return how PICC would respond, that is done according to IS014443 protocol. ISO14443 specifies all the frame formats,PICC command and their format , modulation schemes for RFID technology.

PICC Frame formats:

- Short Frame:

- Standard Frames

PICC Command Set:

- REQA/WUPA Command: This command is send by PCD to scan the valid and IS014443 compatible PICC’s. This command is in short frame format. Host MCU will write this command into the PCD FIFO, from where this command is transmitted and emitted wirelessly. Response to this command is with ATQA. PICC are in Idle state when listening to this command and after successfully transmitting the ATQA response they enter into Ready State. These commands consist of 7 bits, as specified below:

- ANTICOLLISION/SELECT Command: PICC are in ready state when listening to this command and after this command they enter into ACTIVE STATE. This Command is used to get the UID of the scanned PICC and further select the corresponding PICC for Reading and writing data from it. For the MF1S503 PICC’s UID is of 4 bytes, for that only 1 cascade level is needed.

These commands need to be configured and then these bytes are written into The PCD FIFO for transmission and emission of signal to PICC wirelessly. This Command consists of:

- Select code SEL(1byte): Specify the cascade level.

- No of valid bits NVB (1 byte): specify number of bytes that would be transmitted by PCD to PICC (including SEL, NVB and below point)

- 0 to 40 data bits of UID according to value of NVB.

ANTICOLLISION Command consist of:

- Select Code: Cascade level 1= 0x93

- No of valid bits NVB = 0x20

Response to ANTICOLLISION Command is with the UID of the Scanned PICC(0xEA, 0x24, 0x77, 0x15) and its CRC(0xAC).

- SELECT Command consists of:

- Select code: Cascade level 1 = 0x93

- No of valid bits NVB – 0x70

- 0 to 40 data bits of UID that has been received in ANTICOLLISION Command( 0xEA, 0x24, 0x77, 0x15)

- CRCA(1 byte) : CRC of SELECT Command would be calculated by PCD and then it would be sent to PICC. And When PICC receives the SELECT Command it will check this CRCA and then will send the ACK.(0xAC)

Response to SELECT Command is with the Select Acknowledge:

MFRC522 Hardware and Pinout

MFRC522 IC has 32 pins in total and it comes in SOT617-1 package.

Pin description can be found from the datasheet of MFRC522. To use the MFRC522 IC its module is widely available and quite inexpensive. Can be brought from Robu at cost of 150 rupees. With the module an RFID tag and a key fob tag of MIFRAME Classic 1KB comes in.

In MFRC522 module, IC has 8 pins exposed out for connection and connecting to host MCU.

- The module has 4 pins exposed out for connecting it to host MCU using either SPI, I2C or UART. By default, reader can communicate with a microcontroller over a 4-pin SPI with a maximum data rate of 10 Mbps. It also supports I2C and UART protocols. As told in MFRC522 functional description part, MFRC522 checks the host interface type automatically depending on the signals on it’s control pins.

- MFRC522 module has 1 interrupt pin also exposed out, which can be used to trigger interrupts to alert the microcontroller when a RFID tag is in the vicinity.

- And remaining 3 pins are power supply pins and a reset pin. Reset pin is used for power down mode and reset signal. Module requires the power supply of 3.3 V, that is provided via VCC and GND pins.

Other vendor RFID readers

STMicroelectronics

Texas Instruments

Infenion technologies

Sensor & Modules to explore

Technologies to Explore

Other Blog to Explore

Cryptography Basics/Terminologies

Concept of: Cryptography Ciphers: –> Difference between asymmetric and symmetric ciphers. –> Hashing and MACs –> Concept of certificates, digital signatures, and signing 2) Keys in cryptography –> Key storage, Key generation, key derivation, key import, key export, key configuration, key slots shared secret key, master key and etc 3) Attacks in cryptography –> 4) Miscellaneous things: –> Random number generator, Cryptography Ciphers One-way compression functions One-way compression functions: In cryptography, a one-way compression function is a function that transforms two fixed-length inputs into a fixed-length output. One-way compression functions are built from block ciphers. Some methods to turn any normal block cipher into a one-way compression function are Davies–Meyer, Matyas–Meyer–Oseas, Miyaguchi–Preneel (single-block-length compression functions) and MDC-2/Meyer–Schilling, MDC-4, Hirose (double-block-length compression functions). These methods are described in detail further down. Miyaguchi-Preneel Compression function: is used inside SHE standard cryptography A common use of one-way compression functions is inside cryptographic hash functions. Most widely used hash functions, including MD5, SHA-1 (which is deprecated[2]) and SHA-2 use this construction. Using a block cipher to build the one-way compression function for a hash function is usually somewhat slower than using a specially designed one-way compression function in the hash function. This is because all known secure constructions do the key scheduling for each block of the message. Black, Cochran and Shrimpton have shown that it is impossible to construct a one-way compression function that makes only one call to a block cipher with a fixed key.[6] In practice reasonable speeds are achieved provided the key scheduling of the selected block cipher is not a too heavy operation. But, in some cases it is easier because a single implementation of a block cipher can be used for both a block cipher and a hash function. It can also save code space in very tiny embedded systems like for instance smart cards or nodes in cars or other machines A compression function mixes two fixed length inputs and produces a single fixed length output of the same size as one of the inputs. This can also be seen as that the compression function transforms one large fixed-length input into a shorter, fixed-length output. 2) Block Cipher: Block ciphers take (like one-way compression functions) two fixed size inputs (the key and the plaintext) and return one single output (the ciphertext) which is the same size as the input plaintext. modern block ciphers are only partially one-way. That is, given a plaintext and a ciphertext it is infeasible to find a key that encrypts the plaintext to the ciphertext. But, given a ciphertext and a key a matching plaintext can be found simply by using the block cipher’s decryption function. Thus, to turn a block cipher into a one-way compression function some extra operations have to be added. Some methods to turn any normal block cipher into a one-way compression function are Davies–Meyer, Matyas–Meyer–Oseas, Miyaguchi–Preneel (single-block-length compression functions) and MDC-2, MDC-4, Hirose (double-block-length compressions functions. Stream Cipher: AES: ECB mode: CBC mode: MAC generation/verification: Compression Function Cryptographic Keys Types of keys in cryptography: What Is Secret Key Cryptography? A Complete Guide – Helenix Secret Key: the key which is used in symmetric ciphers is a called as secret key. As this is single key which can be used for both encryption/decryptions, thus it is called as secret key. Private key: private key is used in asymmetric key cryptography, where there are 2 different keys for encryption and decryption. Key Usage flags: Different keys are used for different features and specs. So, there are concept of flags through which we can specify which key is to be used for what purpose and its usage limitation. Broadly there are x number of fields in Key usage: Key derivation: A Key derivation function (KDF) is a basic and essential component of cryptographic systems: Its goal is to take a source of initial keying material, usually containing some good amount of randomness, but not distributed uniformly or for which an attacker has some partial knowledge and derive from it one or more cryptographically strong secret keys. There are many forms of KDF’s, and not all functions used as KDF are explicitly named as KDF’s. For instance, the KDF of TLS is simply called “the PRF” for Pseudo-Random-Functions, which is a much more generic term Some KDF’s have input limitations, some have output limitations and not all KDF’s have the same configuration parameters. The base construction of a KDF is: input: a binary encoded secret or key other information to derive a specific key (optional) output size (if configurable) output: a derived key or derived keying material. Furthermore, there are many different parameters possible: a salt work factor (for PBKDF’s) memory usage (for PBKDF’s) parallelism (for PBKDF’s) Cryptography Miscellenous terms Pseudorandom Function Family(PRF): Author: Kunal Gupta

Essential Terms Related to Microcontroller

Here we will understand the basic terms related to microcontrollers.

What is OLED Technology?

OVERVIEW Nowadays we see oled display being used everywhere be it the phones , TVs , laptops or PCs , smartwatches . They sure are better than old chunky CRT TV displays that were bulky and didn’t deliver the desired picture quality , with the introduction of the LCD and backlight LEDs the things sure got better with the chunkiness of the display gone but the picture quality still wasn’t what one desired of but with the release of the OLED display all these problems became a thing of past. OLED or organic light emitting diode were invented in 1987 by Ching Tang and Steven Van Slyke from Kodak but it was until 2004 when SONY released a OLED TV. In fact in CES 2019 , there were some innovative inventions that were released in the OLED domain with the companies trying to come up with foldable display and some exceptional picture quality. TYPES OF OLED Passive Matrix Oled (PMOLED) Pmoleds have strips of cathode , anode and organic layer. The anode strips are perpendicular to cathode strips it is their intersection that makes a pixel . External circuitry applies current to the cathode and anode strips to decide which pixel to light up. They are used in MP3 players , cell phones etc. Active Matrix Oled(AMOLED) Amoleds have full layer of anode and cathode and organic molecules . The anode layer overlaps the TFT matrix array . The TFT array is the matrix circuitry that decides which pixel gets turned on form the image. Since they consume less electricity they are used in TV screens , BillBoards, Computer Monitors. Transparent Oled A Transparent Oled has all the components cathode, anode, substrate transparent and when off the display is 85 percent transparent. When switched ON the display allows the transfer of light in both the directions. Top Emitting Oled The Top Emitting Oled is have substrate that is either opaque or transparent . They are best suited for active matrix design . They are used in smartcards Foldable Oled They are substrate that made of flexible metallic foil , plastic . They are durable and are easier to replace in case of damage . They are used in smart clothing , GPS receivers , IC computers. White Oled They are made of white light that is more uniform and energy efficient rather than fluorescent lights. They posses true color of incandescent lights BESIDES THESE OLEDS ARE ALSO CATEGORIZED ON THE BASIS OF BASE COLOUR Monochrome Blue Monochrome white Yellow Colour NO OF PINS 3 Pins (supports only I2C) 7 Pins(supports both I2C and SPI) BASED ON INTERFACE ICs SSD1306 SSD1331 BASED ON SIZE 0.91 inch(128×32) 0.96 inch(128×64) HOW OLEDs WORKS Both the LCD and OLED have similar display mechanism . The difference lies in the fact that OLED has the smallest display unit made of pixels that are usually 0.3mm x 0.3mm . Inside each pixel they are 3 different type of color filters . When the size of the color filter is reduced then human eye losses its ability to view each color individually and sees them as a mixture. Next each pixel is converted into digital form for future reproduction of the image. Earlier the image reproduction was done using backlight white , colour filters, glass , diffuser . When the light would glow each color filter would light up too. Behind the filters a polarizer lcd sheet is used which reproduces the image , the problem with this was the black colour produced wasn’t exactly black due to the back light being ON constantly . This issue was rectified using tiny light sources for each pixel due to which organic led was used . If we apply positive voltage to the anode termina the electrons would combine with the holes in the LUMO layer producing light. Work is also being done to remove the need for light source and add doping material in the emission layer which will release light of the certain color due to the energy difference in the conduction and valence layer corresponding to their wavelengths FIG -1 SIZE OF A SINGLE PIXEL FIG-2 RGB COLOR FILTERS INSIDE A PIXEL FIG -3 CONVERTING EACH COLOR INTO BINARY FIG -4 CROSS SECTION VIEW OF OLED FIG-5 CHANGING THE ORIENTATION OF THE POLARIZER TO GENERATE DIFFERENT COLORS FIG -6 ELECTRON HOLE PAIR COMBINATION TO GENERATE LIGHT FIG – 7 DOPING OF SUBSTRATE TO GENERATE LIGHT OF VARIOUS WAVELENGTH USE CASES OF OLED DISPLAY Raspberry Pi Based SSD1306 OLED Video PlayerThis project uses Raspberry pi and OpenCv to display videos on the Oled display ESP8266 Weather WidgetThis project used ESP8266 and weather API to display real time weather conditions on the 0.96 inch display. Tinyduino gamepadThe project used joystick , push buttons , arduino uno , custom designed PCB , USB module and ssd display to play games on the tiny 0.96 inch screen Bluetooth SmartwatchThe project uses 0.96 display , bluetooth module , tiny arduino , lipo battery to connect to the phone and display all kinds of medical stats and time Speedometer for bikes The project uses gps module neo6m and ssd1306 display to show speed of the vehicle on the display and raise an alarm in case of overspeeding. HOW TO CONNECT THE DISPLAY WITH THE MICROCONTROLLER WE WILL BE COVERING THE DETAILS ON HOW TO CREATE AN EMBEDDED DRIVER FOR THE DISPLAY IN THE NEXT BLOG . IN THIS WE’LL BE COVERING A BRIEF OVERVIEW OF THE 2 METHODS THAT CAN BE USED TO COMMUNICATE WITH THE DISPLAY. I2C SPI I2C Using I2C we’ll be communicating with the microcontroller by the help of SCL the clock

GPIO Peripheral in S32K144 MCU

Table of Contents So hello guys, welcome back to NXP Semiconductors S32K144 MCU Tutorial series. In the last blog we just started with S32K144 MCU. In this blog we are going to explore the first peripheral of this MCU. Going to Start with GPIO peripheral. Objective would be to get familiarity with GPIO peripheral for S32K144 MCU. Would be understanding GPIO peripheral from Hardware point of view in S32K144 MCU. Going to understand the how to use GPIO peripheral via S32K SDK/pins driver. Would also be demonstrating the blink LED sketch for GPIO in the end. So read along the blog and do tell me its reviews! GPIO Peripheral Theory General Purpose Input/Output(GPIO) is a crucial peripheral in microcontrollers, enabling interaction with the external world by sending and receiving digital signals. Digital Signals, here are referenced as High and Low Signals. High signal is +5/+3.3V level and Low Signal is 0V level. As MCU’s are digital devices, so it can only understand High and Low Voltage levels. Almost all the pins of the Microcontroller are by default part of the GPIO peripheral, accept from the power pins. Every Pin can be configured in Input or Output State. State of Pins When a pin is configured as Input State, it can detect the level of external signal whether it is high signal or low signal. For example when we press the button, MCU process that as a external signal. Button is connected to one of the GPIO pins of the Microcontroller, which is being configured as Input state and when we press the button a High or Low voltage signal is generated. Which voltage level is generated? is detected by the configured GPIO Pin. When a pin is configured as Output State, it can generate the High Signal or Low Signal to drive the external electronic devices. For example, LEDs are electronic devices which needs High signal to power-on them and low signal to power-off them. So LEDs are connected to one of the GPIO pins of the Microcontroller, which is being configured as Output State and then by programming we can configure the signal that has to be generated from the corresponding configured GPIO pin. Input/output are defacto states of pins, apart from these 2 there are other states too, on which pins can be configured. State of pins can be: Output Input PullUp PullDown Tri-state GPIO pins categorization GPIOs are organized into banks, each requiring a unique identifier to identify a specific pin. These identifiers are commonly referred to as “Ports” and “Pads”. With the vast number of pins available on a microcontroller, it is essential to have a mechanism to reference and utilize them effectively. To simplify this process, GPIO pins are now divided into Ports, with each Port containing a multiple of 8 pins. This division allows for easy referencing and addressing of the pins on the microcontroller. By utilizing this system, developers can efficiently access and manipulate the GPIO pins on a microcontroller, streamlining the development process and improving overall functionality. GPIO In S32K144 MCU In S32K144 MCU, there are 5 ports of GPIO: named as PTA to PTE. Each Port pin has 16 pins. In S32K144 reference manual, GPIO peripheral is being dicided into 2 modules: PORT (Port Control and Interrupt Module) and GPIO (General Purpose Input/Output Module). PORT Module is responsible for Interrupt and Port Control Operations (Like alternate functions, Pull-up/down, drive strength) of the above Ports specified. GPIO module is responsible only for Controlling Input/Output directions of the port pins. Features of GPIO in S32K144 MCU Pins can be configured as Output. Pins can be configured as Input. Pins support the multiplexing of signals, so that a single pin can be do different job(refer to signal multiplexing section). Dedicated Port Output registers for set/clear/toggle the bits. Efficient bit manipulation of the general-purpose outputs is supported through the addition of set, clear, and toggle write-only registers for each port output data register. GPIO module can operate on 3 modes: Run Mode, Stop Mode and Debug Mode GPIO Module is clocked by System clock. GPIO module has a feature of Lock feature, in this feature we can lock the Mode of operation of PIN in one Power Cycle. Registers of GPIO in S32K144 For simplicity, each GPIO port’s register appear with the same width of 32 bits, corresponding to 32 pins. The actual number of pins per port in S32K144 is 16 pins. So we will be addressing only first 16 bits of the registers, on last remaining 16 bits are irrelevant for us. But in S32K144 there are 16 pins only per port, so we will be accessing only first 16 bits of the registers (0-15), reading & writing on (16-31) will have no effect. In S32K144, there are registers to support 8bit, 16-bit and 32-bit access. Registers of GPIO: GPIO Data Direction register: Direction of GPIO pin GPIO output data register: Output direction of GPIO pin GPIO Input Data Register: Displays the logic value on each pin Efficient bit manipulation of the general-purpose outputs is supported through the addition of set, clear, and toggle write-only registers for each port output data register. Each Port of GPIO has 16 pins. And each pin is referenced as each bit of the above registers. Features of Pin configured as Output: Output: Pin is configured for the GPIO Function and corresponding port data direction register bit is set. For efficient bit manipulation, there are dedicated output registers for toggling, Set High or Set LOW the pins. Instead of doing the manipulation of pin signals via software using bit manipulation and shifting Features of Pin Configured as Input Input: If Pin is configured for the GPIO function and the corresponding port data direction register bit is clear. GPIO Hardware/Pinout in S32K144 MCU S32K144 MCU comes in 3 pin counts: S32K144_100lqfp, S32K144_64lqfp, S32K144_48lqfp. The one which we will be using is S32K144_100lqfp. S32K144 EVB board which is explained in last blog, has S32K144 MCU of S32K144_100lqfp packaging.  For GPIO

What is Altium CircuitStudio?

Altium Circuit Studio is an entry-level but professional PCB design suite. Which offers interactive automated routing, intuitive ECAD-MCAD collaboration, integrated SPICE simulations, and unparalleled design efficiency at an affordable price point. Often compared to KiCad because of the small difference in price point. Altium CircuitStudio comes with a perpetual licence fee of $495. With its native 3D, version control and over 300,00 component library and the Altium promise. This software will definitely prove to be better than others in its class. Opening up this software showcases a deliberately minimal interface that requires lesser resources to run on your computer. This showcases the demographic this product is aimed towards. Exactly as it says on the box entry-level professionals or freelancers or undergraduate students. This is not a full-professional product which is made evident by some things like, not being able to multi-object drag and drop, remapping hotkeys (this is a very mouse-heavy program), and no.DbLib support. CircuitStudio is unable to define its place, for a perpetual license fee of $495 you get 90% of the features of Altium Designer but those last 10% are the real challenge, this means that software is limited to designing low-level PCBs, which can be good for a freelance, but the price at which you get this software may just be too high for a graduate student willing to pay $120 per year for the Altium Designer student version, but without the ability to sell your designs, which CircuitStudio offers. The best thing which circuit studio offers at this price point is the Altium component library. This software is a good investment to start your PCB design and schematic journey while getting hands-on lessons and tutorials straight from the Altium community. Author: Kunal Gupta

Secure Hardware Extension: Cryptography peripheral for automotive chips

The more realistic you get, the more distinct you become in modern world Gettobyte What is SHE (Security Hardware Extension) Technology? Secure Hardware Extension, short form SHE: is a standard that specifies performing basic cryptography ciphers and managing cryptography keys via automotive Microcontrollers. SHE has been stated as standard in automotive microcontrollers to protect the cryptographic keys from software attacks by hardening them into the memory of the microcontroller and to perform basic symmetric cryptographic ciphers like AES & CMAC for encrypting and decrypting the data. SHE standard is implemented in microcontrollers by having an on-chip extension(peripheral) as a security subsystem which follows, the SHE standard. SHE standard is stated by hersteller-initiative-software (HIS) consortium in April 2009. This consortium was founded in 2004 and consists of members from Audi, BMW, Daimler, Porsche, and Volkswagen to address activities and develop common automotive manufacturing standards. SHE standard states that the peripheral in the Microcontroller should have the following 3 blocks, to implement SHE standard in MCU: Control Logic: Connecting the parts of the CPU to the microcontroller. Storage Area: To keep the cryptographic keys and additional corresponding information. Cryptographic cipher core: a hardware core or module to perform necessary calculations for performing cryptographic ciphers. Automotive Chips, which have SHE peripheral: MPC5646C Freescale MCU’s S32K144 NXP Semiconductor’s MCU Components of SHE Technology SHE Technology Why SHE Technology? Working principal of SHE Technology? USE cases of SHE Technology? How to use SHE Technology? Add Your Heading Text Here Author: Kunal Gupta

Author: Kunal Gupta

Author