Automotive Development board to enable hassle free learning and development across multiple automotive technologies

Overview So hello guys, welcome to series of Microcontroller tutorials. As Microcontrollers are big thing happening across the globe, but to learn

So hello guys, welcome to series of Microcontroller tutorials. As Microcontrollers are big thing happening across the globe, but to

SPI Peripheral in S32K1 Microcontrollers. How to use SPI peripheral of S32K1 MCU’s?SPI Master and Slave configuration and API’s

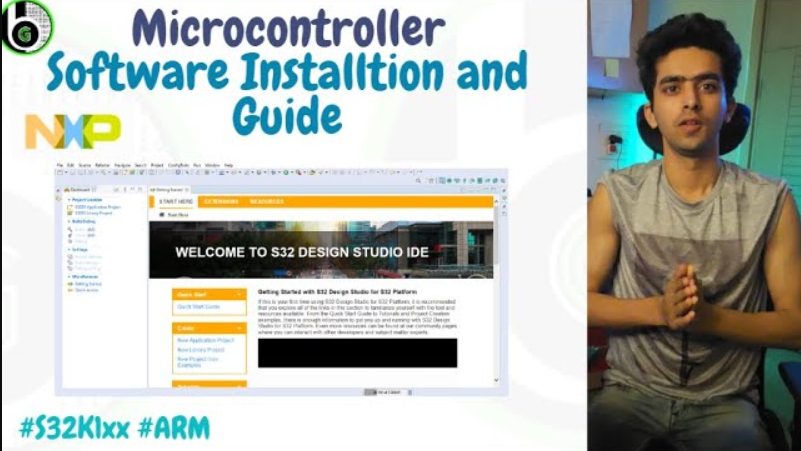

S32 Design Studio IDE Softwrae Installation and SDK installation for S32K144 MCU’s

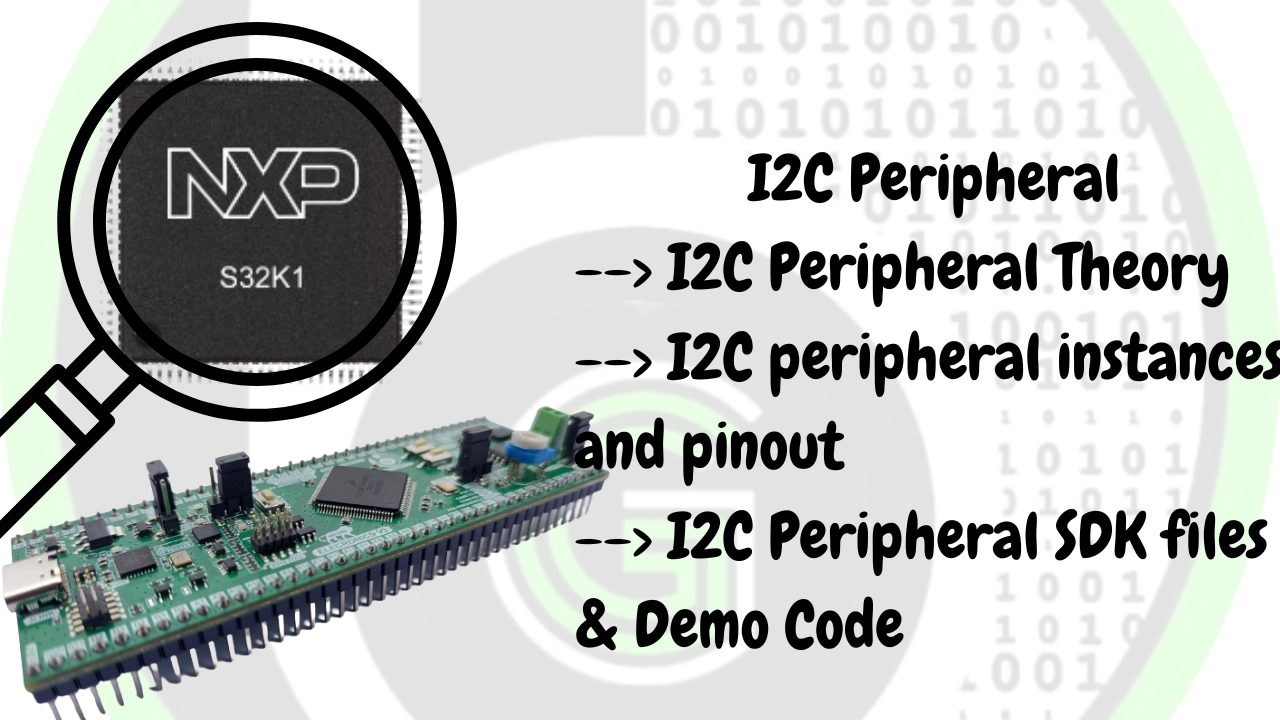

I2C Peripheral in S32K1 Microcontroller. How to use I2C peripheral of S32K1 Microcontrollers

What is Microcontroller Technology??? How to start learning about Microcontrollers technology

LPUART Peripheral in S32K144 MCU || Briefing about LPUART Peripheral in S32K1xx MCU’s

Table of Contents About GPIO Peripheral The pins which can be configured by the software at runtime to perform various

Table of Contents About STMicroelectronics STMicroelectronics is a leading provider of semiconductor solutions that are seamlessly integrated into billions of