About ARM Processor’s

What is a Processor

Processor is programmable electronic circuitry that performs operations according to the instructions stored in memory. The processor as of itself does not have the memory and I/O devices. The processor reads the instructions stored in the memory, interprets it, and stores the output in memory or signals the I/Os. Processor Consists of the Processor core which contains circuitry for instruction fetching, decoding, and execution, register banks, and control units.

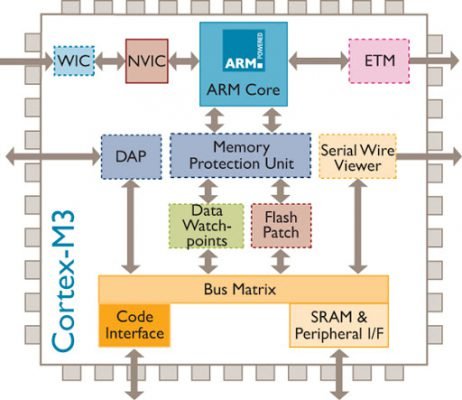

According to the architecture design of the processor, the different processors have different components. For example, ARM cortex-M4 processors have NVIC, MPU, Floating point units, optional debug subsystems.

Fig 1.1 – Block Diagram of the Cortex-M3 and Cortex-M4 Processor.

The processor is the part of the Microcontroller and not a microcontroller as a whole and it takes only a small part of the silicon area. Processor design companies design the processors and various components that silicon designers need and license these designs to various silicon design companies including microcontroller vendors. These designs are called Intellectual Property (IP) and the business model is called IP licensing. Although many microcontroller vendors use ARM processors as their choice of CPU, the memory system, memory map, memory size, and peripherals can be completely different from one product to another.

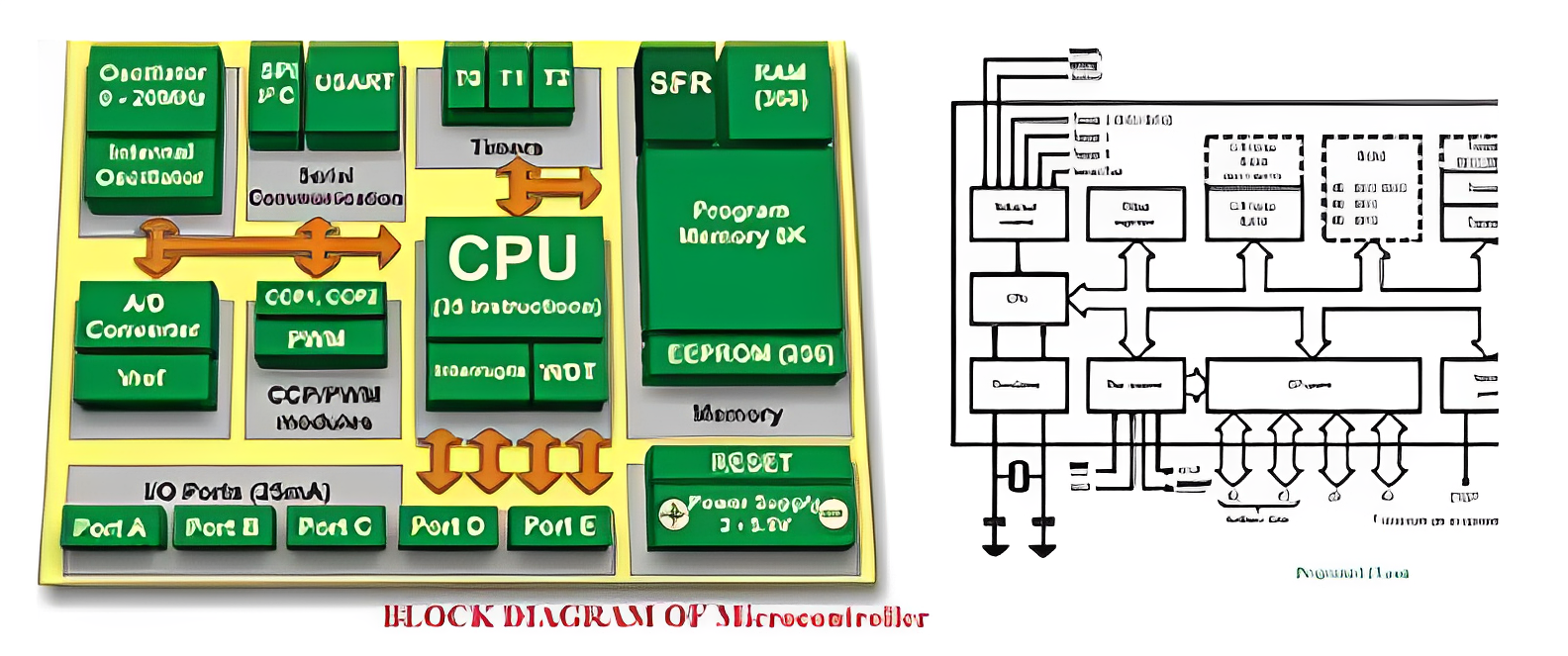

This allows the microcontroller vendors to design differently. A block diagram of the microcontroller.

Fig 1.2 – A microcontroller contains Many different blocks

How does Processor control the world?

Processors become an integral part of our life. We come across many devices which have processors embedded in them. For example:

- The smartphone on which I am writing this article has ARM cortex-A55 and cortex-A75 as processor,

- The Famous Tesla motors FSD Self-driving computer has many ARM processors.

To give the idea of how processors are running the world look at these two examples.

- Upto 2019, Arm partners have shipped more than 160 billion Arm-based chips.

- Due to the shortage of semiconductor chips(processors) many car manufacturing companies had to reduce the number of cars manufactured.

ARM Processor

ARM processors are designed by ARM Ltd., ARM does not manufacture processors or sell the chips directly. Instead ARM licenses these designs to other semiconductor companies so that they can make their processor, microcontroller, SOCs as ARM processors are configurable. In the Cortex processor range, the processors are divided into three profiles:

1) The A Profile is designed to handle complex applications such as high-end embedded OSs.

2) The R profile processors are targeted primarily at the high end of the real-time market. These are applications, such as hard drive controllers, automotive systems, etc.

3) The M profile processors target smaller-scale applications such as microcontrollers and mixed-signal design.

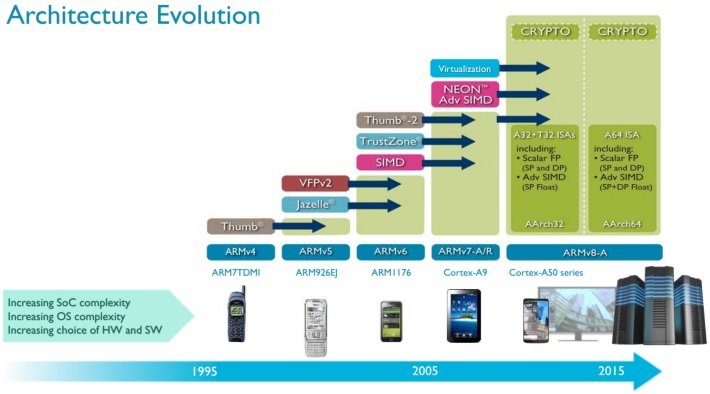

ARM develops new processors, new instructions, and architectural features are added from time to time, as a result, there are different versions of the architecture. For example:

- ARM7TDMI is based on the architecture version ARMv4T.

- ARMv5TE architecture was introduced with the ARM9E processor families.

- With the ARM11 Processor family, the architecture was extended to ARMv6 with memory system features and SIMD instructions included.

- Cortex family processors are based on ARMv7 and ARMv6.

The cortex-M3 and cortex-M4 processors are based on ARMv7-M architecture. The architecture evolution of the ARM can be seen in the following (Fig 1.4). All the cortex-M processors support Thumb-2 technology(16-bit and 32-bit instructions), with no need to switch the processor between Thumb state and ARM state.

Figure 1.4 : Evolution of ARM

Figure 1.5

STM32 series is shown

How to ARM Processor based MCU's ?

The language used to program MCU is C/C++, but mostly C is used. There are many development suites available from open-source free tools, to budget low-cost tools, to high-end commercial, to mcu vendors propiatery IDE’s. packages. Some development toolchains are:

For Programming and debugging ARM Processor based MCU’s, we will be using Microcontrollers of different vendors like: STMicroelectronics and NXP Semiconductors.

We will be using STM32 Family of STMicroelectronics and S32 Family of NXP Semiconductors. Both of these are based on ARM Processor and have rich set of features and specifications which are ideal for learning embedded systems.

Now both the companies provide their own IDE’s for : STM32CubeIDE and S32 Design IDE for respective family of MCU mentioned above.

Or we can also use the Above-mentioned IDE’s which are general IDE’s can be used to program any ARM processor based MCU. But recomended one is to use Vendor specific IDE as it has many extra featutes for programming.

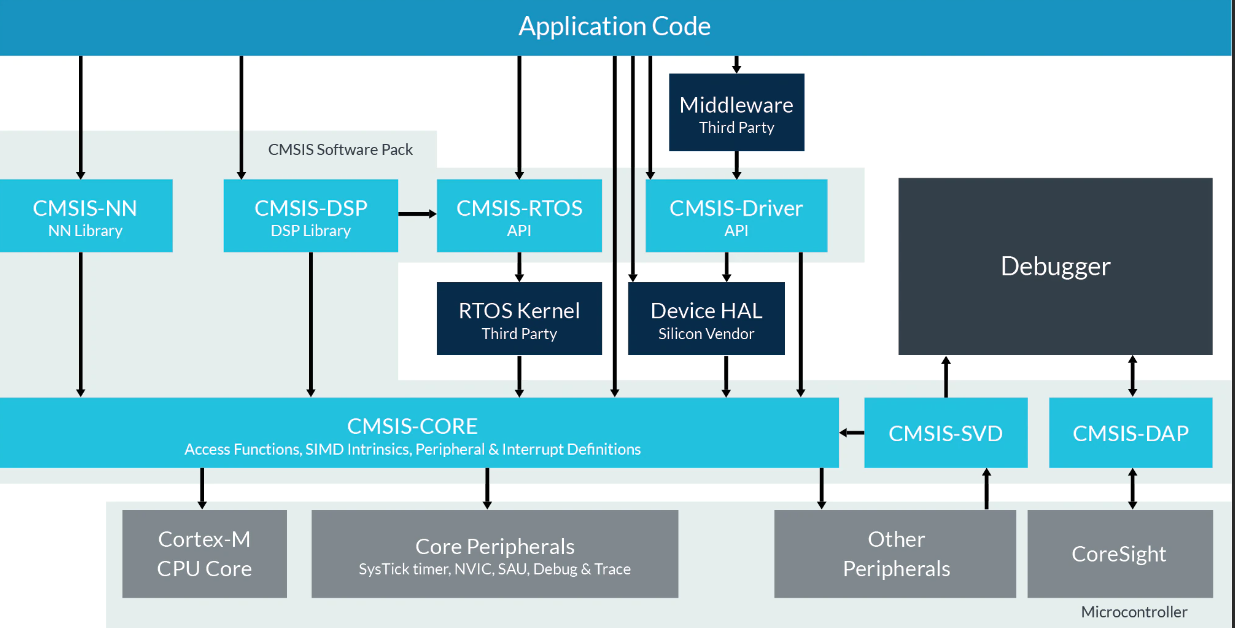

CMSIS

The Common Microcontroller Software Interface Standard(CMSIS) was developed by ARM to allow microcontroller and software vendors to use a consistent software infrastructure to develop software solutions for cortex microcontrollers.

THE AIM OF CMSIS:

- Software reusability: make it easier to reuse code with different Cortex-M processors, reducing time to market and verification efforts.

- Software compatibility: Due to consistent software infrastructure, software from various sources can work together, reducing the risk in integration.

- The CMSIS allows easy access to processor core features from the c language.

- CMSIS-compliant device drivers can be used with various compilation tools.

CMSIS started out as a way to establish consistency in device-driver for the Cortex-M microcontrollers, and this has become CMSIS-Core.

Since then, additional CMSIS projects have started:

A set of APIs for applications developers to access the features on the Cortex-M processor regardless of microcontroller devices and toolchain used.

This library is intended to allow software developers to create DSP applications on Cortex-M microcontrollers easily.

the System View Description in an XMl-based file format to describe peripheral set in microcontroller products.

the CMSIS-RTOS is an API specification for embedded OS running on Cortex-M Microcontrollers.

the CMSIS-DAP(Debug Access Port) is a reference design for a debug interface adaptor, which supports USB to JTAG/Serial protocol conversions.

The CMSIS files are integrated into device-driver library packages from the microcontroller vendor. So when you are using CMSIS-compliant device-driver libraries provided by the microcontroller vendors, you are already using CMSIS.

We can define the CMSIS into multiple layers:

Name definitions,address definitions, and helper functions to access core registers and core peripherals. This is processor specific and is provided by ARM.

Name definitions, address definitions of peripheral registers etc. This is device specific.

Access Functions For Peripherals

How do I use CMSIS-Core ?

Add Source files to the project. This includes:

- Device specific, toolchain-specific startup code, in the form of assembly or C.

- Device-specific device initialization code(e.g. System_c).

Add header files into the search path of the project:

- A device-specific header file for peripheral registers definitions and interrupt assignment definitions(e.g., .h)

- A device-specific header file for functions in device initialization code(e.g, system_.)

- A number of processor-specific header files(e.g, corre_cm3.h,core_cm4.h)

- Optionally additional vendor-specific header files for peripheral access functions.

The IDE automatically sets up the startup code for you when you create a new project. Otherwise, you just need to add the startup code from the device-driver library to the project manually. Startup code is required for the starting sequence of the processor, and it also includes the exception vector table definition that is required for interrupt handling.

STM32 HAL is an abstract lawyer ensuring minimized portability across the STM32 Portfolio. HAL APIs are available for all peripherals. These hide the MCU and peripheral complexity from the end-user.

Low-Layer APIs(LL) offer a fast lightweight layer that is closer to the hardware than the HAL. LL APIs are available only for a set of peripherals. These require deep knowledge of the MCU and peripheral specifications.

CONCLUSION PARAGRAPH: In this article, we just scratched the surface of the embedded world. In the upcoming articles, we will learn embedded development by doing projects.

Next Blog To Read for STM32

GPIO Peripheral in STM32F103 MCU

Table of Contents GPIO Theory So now we’ll talk about GPIO pins . GPIO stands for general purpose input output pins; they are the means for communication between the microcontroller and the external world (using sensors etc).It is signal that arrives on these pins or a signal that is sent or written on these pins that facilitates this communication. These pins can be configured to act as input or output via the application software(in our case stm32cube ide). The programmer can configure the pins as LOW or 0V or HIGH or 3.3V(or 5V ). These GPIO pins can also be configured to act as special purpose pins as well where their alternate functionality is exploited . These alternate functionality includes UART , ADC , SPI etc . In the case of UART communication, Transmitter(Tx) and Receiver(Rx) pins are required. GPIO pins can be configured to act as TX or RX pins . Even in ADC the pins are configured to act as Analog pins having 12 bits of resolution . The alternate functions of various pins are shown below: Input floating Input pull-up Input pull-down Analog Output open-drain Output push-pull Alternate function push-pull Alternate function open-drain GPIO Peripheral in STM32F103 All the pins of STM32F103 are grouped in multiple ports as PORT A, PORT B, PORT C As can be seen from Pin configuration chart in the PA1 stands for Port A Pin 1. There are 37 GPIO pins in stm32f103 which are divided as PORT A with 16 pins, PORT B with 16 pins, PORT C with 3 pins and PORT D with 2 pins. Each GPIO port has two 32-bit configuration registers (GPIOx_CRL, GPIOx_CRH), two 32-bit data registers (GPIOx_IDR, GPIOx_ODR), a 32-bit set/reset register (GPIOx_BSRR), a 16-bit reset register (GPIOx_BRR) and a 32-bit locking register (GPIOx_LCKR). In the register names, x stands for the port to which pin belongs. If we are configuring pin PA1, it has Port A then registers would be accessed by GPIOA_CRL and etc. Out of above-mentioned registers, GPIO peripheral has 2 most important registers: Direction Register(GPIOx_CRL, GPIOx_CRH)</h3 > Direction register: Set the corresponding pin as input/output pin. Data register(GPIOx_IDR, GPIOx_ODR)</h3 > Data register: where we set the Logic level (High (1)/Low (0)), for the corresponding pin if it is configured as output pin or we read the Logic level (High (1)/Low (0)), for the corresponding pin if it is configured as input pin. Pin Configuration Chart Pin Definitions GPIO Peripheral Block Diagram in STM32F103 First after selecting the pin the port is decided Then after following the arrow the busses are selected based on it: APB/APB1 or AHB After which the clock is enabled to the particular port using either __HAL_RCC_GPIOX_CLK_ENABLE() function or using the RCC AHB1 peripheral clock enable register and selecting the port to which clock has to be provided by enabling it. Methods to configure the GPIO Peripheral Configuring the busses i.e AHB1, AHB2, APB1, APB2 . The AHB bus is faster than APB bus and in case of certain modules they are connected to the same bus .Hence it depends upon the application which bus to use. As can be seen from the picture below the AHB1 takes clock to PORT A , PORT B , PORT C etc . Hence to initialize a pin to a particular port the in RCC AHB1 clock enable register GPIOEN is set to 1 (For Port A GPIOAEN , For Port B GPIOBEN etc) Enabling the clock to that port otherwise the particular pin will not be functional Creating an instance of the structure and then using the members of the structure set the following:- PIN – Takes the pin no as input GPIO_PIN_X {where X -0 to 15} MODE– Selects the mode the specified pin is supposed to work in . It takes in value Output Push Pull ,Output Open drain PULL- It selects the initial value of the pin and takes value no pull up no pull down, pull up or pull down SPEED- Selects the speed of the working of the specified pin i.e low, medium or high ALTERNATE- Specifies the alternate function performed by the pin UART TX OR RX , ADC etc, GPIO Peripheral SDK using STM32HAL We are going to use STM32 HAL SDK for using the GPIO peripheral of the STM32F103. STM32HAL is a very versatile and robust Software package for using Peripherals of the STM32 Microcontroller family. To know more about STM32HAL, refer to this link. Each STM32 HAL has drivers for all the peripherals of the STM32 Microcontroller(One can navigate to the Driver folder in the STM32F1 HAL local repo installed). These drivers can be configured and enabled to use in the project via the STM32 CubeMX configuration tool, which is also integrated into STM32CubeIDE( just like told in the above section for configuring GPIO peripherals). Will be digging into that part, in the next section. For now, let’s understand the STM32HAL GPIO SDK for STM32F103 MCU. stm32f1xx_hal_gpio.c: This file consists of various macros and is responsible for the intialization and configuration of the functions which in turn configures the peripheral. stm32f1xx_hal_gpio.h: consists of various structure definitions that help configure various parameters of the pin, enumeration, and various macros stm32f1xx_ll_gpio.c & stm32f1xx_ll_gpio.h: GPIO Low-level driver source/header file, contains functions that configure the GPIO Peripheral registers at the hardware level. These files are the ones that actually interact with the hardware and make it configurable to our needs.  STM32 HAL Functions for GPIO Peripheral Functions are set of instructions that required to perform certain tasks. In general, a function is first declared in header file(.h) and then it is definied in source file(.c) and then called in main.c or application code. It is of the form function return data type, function name and function arguments. In Embedded functions are required to initialize a peripheral or configure it on the basis of various parameters which are passed on using arguments. This information is then passed on to the registers. List of functions used

STM32F103 & ADC: Single Channel Conversion

In the last post, we have gotten to know about the features of ADC Peripheral that we have in STM32 MCU. Now in this blog with the series of bare Metal Programming for Blue Pill, we will understand different register bytes and bits of ADC Peripheral to be used for using it in different features, configurations, and modes as we get to know about in the Previous Post. In this blog, we will be going through how to use ADC Peripheral for converting a Single Channel of ADC (only one ADC pin) and see its bare metal code. Single Channel Conversion Mode: Only one ADC pin is used, this mode is like when we have say connected only one analog sensor to one of the ADC pins of MCU like the Potentiometer is connected at PA0 pin. ADC Registers In depth for: Let\’s get into an in-depth understanding of which registers and their bits are used for configuring the ADC peripheral of Blue Pill in Single Channel Configuration. We will focus on bits and will give an explanation of why those bits are used for the 1. ADC_SR(ADC status Register) –>This register tells the status of ADC channel Conversion, as it name says. STM32F103 ADC Status Register: 11.12.1 Bit 1[EOC ]: This bit is set by hardware when a single channel of any group (Regular or Injected) is converted successfully. So this bit is used for monitoring when the ADC conversion is completed by using it inside the while loop if interrupts are disabled. 0: ADC Channel Conversion is not completed 1: ADC Channel Conversion is completed When hardware set this bit, we can clear this bit from the firmware end by setting the bit to 0 or by reading ADC_DR(ADC Data Register) Bit 4[STRT]: This bit is set by hardware when regular channel conversion has begun. So when we start the Regular Channel Conversion, we will use this bit inside the while loop to check that whether Regular Channel conversion has started or not. 0: No regular Channel Conversion has started 1: Regular Channel Conversion has started When hardware sets this bit, we can clear this bit from the firmware end by setting the bit to 0. Even if we don\’t clear this bit it will cause no effect during ADC Conversion. But its good practise to clear all bits of Status Register before starting the new conversion 2. ADC_DR(ADC Data Register) –> This register stores the converted digital data at a 12-bit resolution of the converted ADC channel. STM32F103 ADC Data Register 11.12.14 Bit 15:0 [DATA 15:0]: The ADC_DR is divided into two 16 bits groups. The first 16 bits from 0-15 contain the Converted value of the configured ADC Regular Channel. As our ADC is of 12-bit resolution, so this is left aligned or right aligned to 4 bits so as to get the 12 ADC converted data . Left Aligned or Right alignment of ADC Data Depends on ALIGN bit of ADC_CR2 So we will have following code and algorithm for ADC_SR & ADC_DR register:while(!(ADC1->SR & ADC_SR_STRT)) while(!(ADC1->SR & ADC_SR_EOC)); // wait till a group channel converstion has completed adc_data = ADC1->DR; //clear the EOC bit by reading DR register ADC1->SR &= ~ADC_SR_STRT; 3. ADC_CR1(ADC Configuration register 1) –> This register is used for the Configuration of ADC peripheral for Analog Watchdog Discontinuous Mode Interrupt Enable/disable Dual Mode configuration Scan Mode As we are not using any of these features, so all the bits for these registers will be set to zero, and to know about these features and their bit functions, u can navigate to corresponding blogs for those. STM32F103 ADC Configuration Register 1. 11.12.2 Bits 19:16 [DUALMODE 3:0]: These bits are used to configure the type of operating mode. In the blue pill, we have two ADC peripherals: ADC1 & ADC2. We can use these 2 ADC peripherals simultaneously by configuring the respective ADC in different modes or in independent modes. We are going to use these ADC in independent mode as will be using only ADC1 peripheral, so DUALMODE[3:0] will be set to 0. Bit 8[SCAN]: This bit is used to enable/disable the SCAN Mode feature in the ADC peripheral of BLUEPILL. Scan Mode is used when we convert more than 1 channel to scan all the configured channels in a Regular Group. As we are using only a single channel, means only one ADC pin is used so SCAN mode is not used and this bit will be set to 0. 0: Scan Mode disabled. 1:Scan Mode Enabled. So we will have following code and algorith for ADC_CR1 register:ADC1->CR1 &= ~(ADC_CR1_SCAN); // SCAN DISABLED, if using scan mode then dma must be enabled ADC1->CR1 &= ~(ADC_CR1_JDISCEN | ADC_CR1_DISCEN); // Discontinous mode disabled for both injected and regular groups ADC1->CR1 &= ~(ADC_CR1_DISCNUM_2 | ADC_CR1_DISCNUM_1 | ADC_CR1_DISCNUM_2 ); // no channels are configured in discontinous way. // if discontinous mode is enabled then number of //conversions to be done by discontinous mode has to be configured // DISNUM bits ADC1->CR1 &= ~(ADC_CR1_DUALMOD_0 | ADC_CR1_DUALMOD_1 | ADC_CR1_DUALMOD_2); // INDEPENDENT MODE SELECTED ADC1->CR1 &= ~(ADC_CR1_AWDEN | ADC_CR1_JAWDEN); // Analog watchdog disabled for both groups: regular and ibnjected 4. ADC_CR2(ADC Configuration Register 2) –> This register is used for the configuration of ADC Peripheral for: ADC Conversion enables/disabled for regular and injected groups and ADC peripheral enable/disable. Trigger source configuration for regular and injected groups. ADC Data Alignment, DMA, Continous, temperature sensor setting. STM32F103 ADC Configuration Register 2 11.12.3 Bit 0 [ADON]: ADC Peripheral On/OFF. This bit will be set to 1 to enable the ADC peripheral. All channel configurations and ADC Peripheral configurations have to be made before setting this bit to 1. 0: Disable ADC Peripheral 1: Enable ADC Peripheral Bit 1 [CONT]: This bit configures between Single Conversion mode and Continous Conversion mode. Continuous Conversion mode is selected when we have more than 1 ADC channel to be converted. As in this blog, we have

PWM on STM32F103

What is PWM? PWM or Pulse Width Modulation, is a type of digital electrical signal which is periodic in nature, with a rectangular waveform. There are certain terms associated with PWM which we need to understand before we move ahead. Here’s a graphical representation of a PWM signal- · ‘Period’ = Tp , is the time it takes to repeat the same waveform · ‘Duty cycle’ is the time for which the signal is a logic 1 by the total time period. Ton is the time for which the pulse is high Hence, Duty cycle % = (Ton/ Tp) X 100 · ‘Frequency’ = F is the number of times the waveform repeats in a second. So, F = 1/Tp. Applications of PWM signals PWM signals have an extremely wide range of applications, here are a few of them- · Variable voltage generator– if you vary the duty cycle of a PWM signal and apply it to certain electrical components, the components act as if they are receiving analog signals. This is because the response time of the components is finite. So, components like LEDs, buzzers, brushed DC motors etc. can be controlled by PWM signals. Meaning, you could control speed of a motor, brightness of an LED or amplitude of a buzzer and so on. The voltage that they receive has a linear relationship with the duty cycle. So, if logic 1 is 5 Volts 0% duty cycle – 0V 25% duty cycle – 1.25 V 50% duty cycle – 2.5 V 75% duty cycle – 3.75V 100% duty cycle – 5V · As a control signal – Some electrical devices/components analyze PWM signals that they are receiving to give a corresponding output. So, changes in the duty cycle are reflected in the output. These include Servo motors, electronic speed controllers (ESCs) and many more. Here, the devices respond only to specific PWM duty cycles and frequencies If you take the example of servo motors, they can only be operated at 50Hz signal with a duty cycle of 2.5 % to 12% . Anything beyond that doesn’t result in the movement of the servo. (The frequency and duty cycles vary from among different servos, this is a very common value which most 180-degree servos respond to) Similarly, ESCs respond to a PWM signal with ON time of 1ms for minimum throttle and 2ms for maximum throttle with PWM frequency of 50 Hz. Some devices such as HCSR04 ultrasonic sensors give an output as a PWM signal in which the pulse width corresponds to the time it took for the ultrasonic wave to be received. How is PWM signal Generated on STM32?? Timer peripheral STM32 blue pill has 15 pins which can generate a PWM signal, with other models having even more pins for PWM generation. In this section, we will try to understand how PWM signals are generated by STM32 Every microcontroller has a built-in circuit which can measure the passing of time. These are called Timers. What timers essentially do is count up to a certain number and upon reaching that number, they change the value of a certain register to indicate that the timer has counted up to that number. Now, the time it takes to increment this count by 1 is determined by the timer’s clock frequency. So, if the frequency of a timer is 1KHz, its time period will be 1 Millisecond. Hence, if we count up to 10, we have measured the passing of 10 Milliseconds. This is how, by simply incrementing a number, timers can measure the time that has passed since the timer began counting. (This is how the HAL_Delay() function generates delays) The maximum count a timer can make is determined by its register size. So, an 8 bit timer can count up to 28 = 256, 10-bit timer –210 = 1024 16-bit timer –216 = 65536 32-bit timer –232 = 4294967296 So, a 1 bit increase in timer size equals to double the count Timers are extremely necessary for the functioning of a microcontroller as a lot of events in programs are time based, which you may not even realize. Timer Peripheral modes and features Coming to STM32 Blue pill, it has 4 timers of 16-bit size. To perform these functions, they need to be in specific modes. Here are all the modes in which timers can operate in STM32- 1. Input capture mode– In this mode, a pin on the board is set as input on which a PWM signal is sent by some device and we measure the frequency and duty cycle of that signal. This can be used to interface with devices such as HCSR04 ultrasonic sensors, which send a PWM signal as input to the microcontroller, where different parameters of PWM signals can be used to determine the distance which the sensor is trying to measure. 2. Output compare mode– In this mode, the timer is used as a counter and the count is compared to a register which contains a pre-programmed value, when they are equal, a software interrupt is generated and using this, a given pin is switched high or low. This mode comes in very handy when you are making a project which requires you to use multiple peripherals and at the same time generate a rectangular waveform of a given frequency and duty cycle, as it is interrupt based. 3. One pulse mode– In this mode, a pulse can be generated based upon a trigger from an input pin on the board , the pulse generation takes place after a certain delay from when the input trigger pulse was detected. This can be considered as a combination of mode 1&2 (IC &OC) 4. PWM generation mode– In this mode, we can generate a PWM signal on a given pin by fixing a frequency and a duty cycle. This is the mode we will be using to generate PWM signals through the main loop. The difference of this mode to mode 2 (Output compare

Blogs to read for ARM Processor

course navigation

Primary Secondary Success Danger Warning Info Light Dark Link This page is Amazing Author: Kunal Gupta

Tigger MUX Control(TRGMUX) Peripheral in S32K144 MCU

What is TRGMUX peripheral? TRGMUC provides an extremely flexible mechanism for connecting various trigger sources to multiple pins/peripherals. The trigger multiplexer (TRGMUX) module allows software to configure the trigger inputs for various peripherals. The TRGMUX module allows software to select the trigger source for peripherals. TRGMUX is a peripheral which provides mechanisms for connecting various trigger sources to multiple pins/peripherals. Each peripheral that accepts external triggers usually has one specific 32-bit trigger control register. Each control register supports upto 4 triggers and each trigger can be selected from available trigger sources. Author: Kunal Gupta

PDB (Programmable Delay Block) Peripheral in automotive microcontroller (NXP S32K144)

What is Programmable Delay Block(PDB) peripheral? PDB provides controllable delays from either an internal or an external trigger, or a programmable interval tick, to the hardware trigger inputs of ADCs. PDB can also provide pulse outputs that are used as the sample window in the CMP block. The PDB contains a counter whose output is compared to several different digital values. If the PDB is enabled, then a trigger input event will reset the PDB counter and make it start to count. A trigger input event is defined as a rising edge being detected on a selected trigger input source, or if a software trigger is selected and the Software Trigger bit (SC[SWTRIG]) is written with 1 Author: Kunal Gupta

ElecronicsV3 Automotive Board: Arduino of Automotive world || Why to get started with it and how?

Author: Kunal Gupta

What are NXP Semiconductors S32K Automotive Microcontrollers || Why to get started with them and how?

Add Your Heading Text Here Author: Kunal Gupta

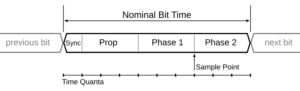

CAN Bit Timing Explained

Bit timing in CAN is all about ensuring that every node on the network can correctly interpret the bits being transmitted. This synchronization is crucial for maintaining the integrity and efficiency of data communication. Bit Segmentation Each bit in a CAN frame is divided into several segments: Synchronization Segment (Sync_Seg): This is the part where the actual synchronization occurs. It’s always one-time quantum (TQ) long and helps align the clocks of all nodes on the network. Propagation Segment (Prop_Seg): This segment compensates for the physical delay in signal propagation across the network. Phase Segment 1 (Phase_Seg1): This is used to compensate for edge phase errors by lengthening the bit time if necessary. Phase Segment 2 (Phase_Seg2): Similar to Phase_Seg1, but it shortens the bit time if necessary. Each of these segments is made up of a certain number of time quanta (TQ), which are the smallest time units in a CAN network. Sample Point The sample point is a critical point within the bit where the bus level is read and interpreted as a logical value. Here’s why it’s so important: Accurate Bit Reading: The sample point is where the CAN controller reads the bit value. It is crucial to set the sample point accurately to minimize errors due to signal noise or other disturbances on the bus. Preferred Value: Typically set at 87.5% of the bit time, this value is preferred by protocols like CANopen and DeviceNet. This means that the bit is sampled after 87.5% of its duration has passed. Adjustable Range: The sample point can vary from 50% to 90% of the bit time, allowing flexibility depending on the network requirements and conditions. For example, ARINC 825 uses a default value of 75%. Noise Minimization: Setting the sample point correctly helps in minimizing the impact of signal noise. Sampling too early or too late can lead to incorrect bit interpretation, especially in noisy environments. Understanding Bit Rate and Bit Timing Bit Rate The bit rate in CAN communication refers to the speed at which data is transmitted over the CAN bus, typically measured in bits per second (bps). The bit rate is a crucial parameter because it determines how quickly data can be sent and received between nodes on the network. Common bit rates in CAN systems include 125 kbps, 250 kbps, and 500 kbps, with some systems operating at even higher speeds, such as 1 Mbps. Bit Timing Bit timing in CAN communication is the precise control of the duration and positioning of each bit transmitted on the bus. Proper bit timing ensures that all nodes on the network sample the bits at the same point, leading to accurate and synchronized data transmission. Bit timing is divided into several segments within each bit time, which collectively ensure robust and reliable communication. How Bit Timing Ensures Synchronization To maintain synchronization, the CAN controller can adjust the length of a bit by an integral number of time quanta (TQ). The maximum value of these adjustments is termed the Synchronization Jump Width (SJW). Hard Synchronization: Occurs on the recessive-to-dominant transition of the start bit. The bit time is restarted from this edge. Resynchronization: Occurs when a bit edge doesn’t occur within the Sync_Seg in a message. One of the Phase Segments is shortened or lengthened, depending on the phase error, up to the SJW. Factors Affecting Bit Rate Four primary factors influence the CAN bit rate: Oscillator Tolerance: Variations in the oscillator frequency can affect the timing accuracy. High-precision oscillators are essential for maintaining a stable bit rate. Propagation Delay: The physical length and quality of the CAN bus can introduce delays. Prop_Seg is adjusted to compensate for these delays. Network Load: Heavy network traffic can lead to delays and timing issues. Proper network design and bit timing configuration help mitigate these problems. Bus Length: Longer bus lengths introduce more propagation delay, requiring adjustments in the Prop_Seg to maintain synchronization. Prescaler Division The prescaler is used to divide the clock frequency to generate the required clock frequency for CAN. For example, if the clock frequency is 48 MHz and we need an 8MHz CAN clock, the prescaler value would be 6. How the Prescaler Division Works Clock Frequency: The original clock frequency provided by the oscillator. Prescaler Value: The value by which the original clock frequency is divided to achieve the desired CAN Clock Frequency. IMPORTANT The CAN system clock is chosen so that the desired CAN bus Nominal Bit Time (NBT) is an integer number of time quanta (CAN system clock periods) from 8 to 25. Time Quanta Definition: The time quantum (tQ) is the basic time unit in CAN bit timing. It is derived from the CAN system clock divided by the prescaler. Calculation: For example, if the CAN system clock is 48 MHz and the prescaler is set to 6, then: Nominal Bit Time (NBT) Definition: The Nominal Bit Time (NBT) is the total duration of a single CAN bit, measured in time quanta (tQ). It is the sum of the time segments within a bit period: Sync_Seg, Prop_Seg, Phase_Seg1, and Phase_Seg2. Components: Sync_Seg: The synchronization segment, always 1 tQ. Prop_Seg: The propagation delay segment, compensates for the signal propagation delay. Phase_Seg1: The first phase segment, can be adjusted to resynchronize the clock. Phase_Seg2: The second phase segment, also adjustable for resynchronization. Calculation: Practical Example of Bit Timing Calculation For calculating Bit Time and Segmentation, some important parameters are taken into account before starting the calculation. Parameters: Bit rate MCU Clock/Oscillator Frequency Bus length Bus propagation delay Propagation delay of TxD plus RxD offered by CAN Transceiver But, usually, values like total propagation delay offered by CAN transceiver, Bus length, and Bus propagation delay, are pre-defined values in their hardware datasheet. Question: Conclusion Understanding CAN bit timing and how the bit rate is adjusted is crucial for ensuring reliable communication in a CAN network. By properly configuring the timing parameters and taking into account factors like oscillator tolerance, propagation delay, network load, and bus length,

Author: Kunal Gupta

Author