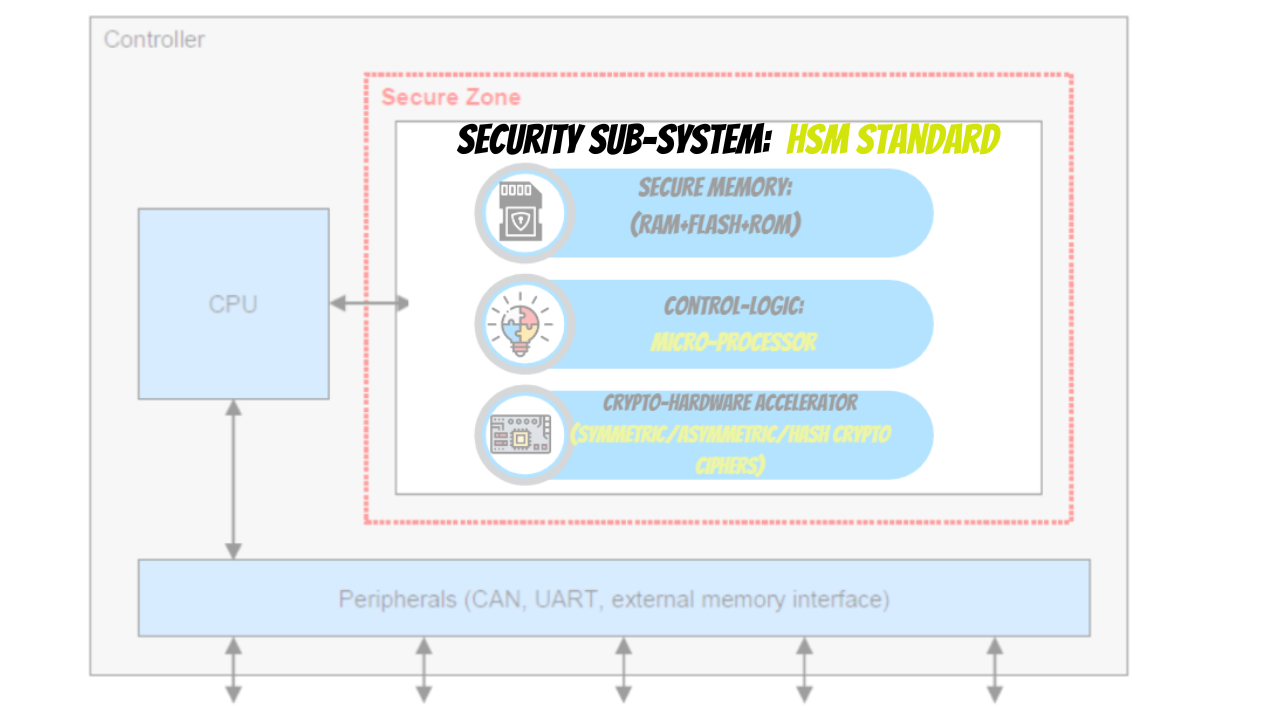

Learn About Advance Cryptography Peripheral in Microcontrollers: The HSM Peripheral (Hardware Security Module)

Now in This blog, we are going to dip deeper into different electronics sub-systems in an automotive vehicle.

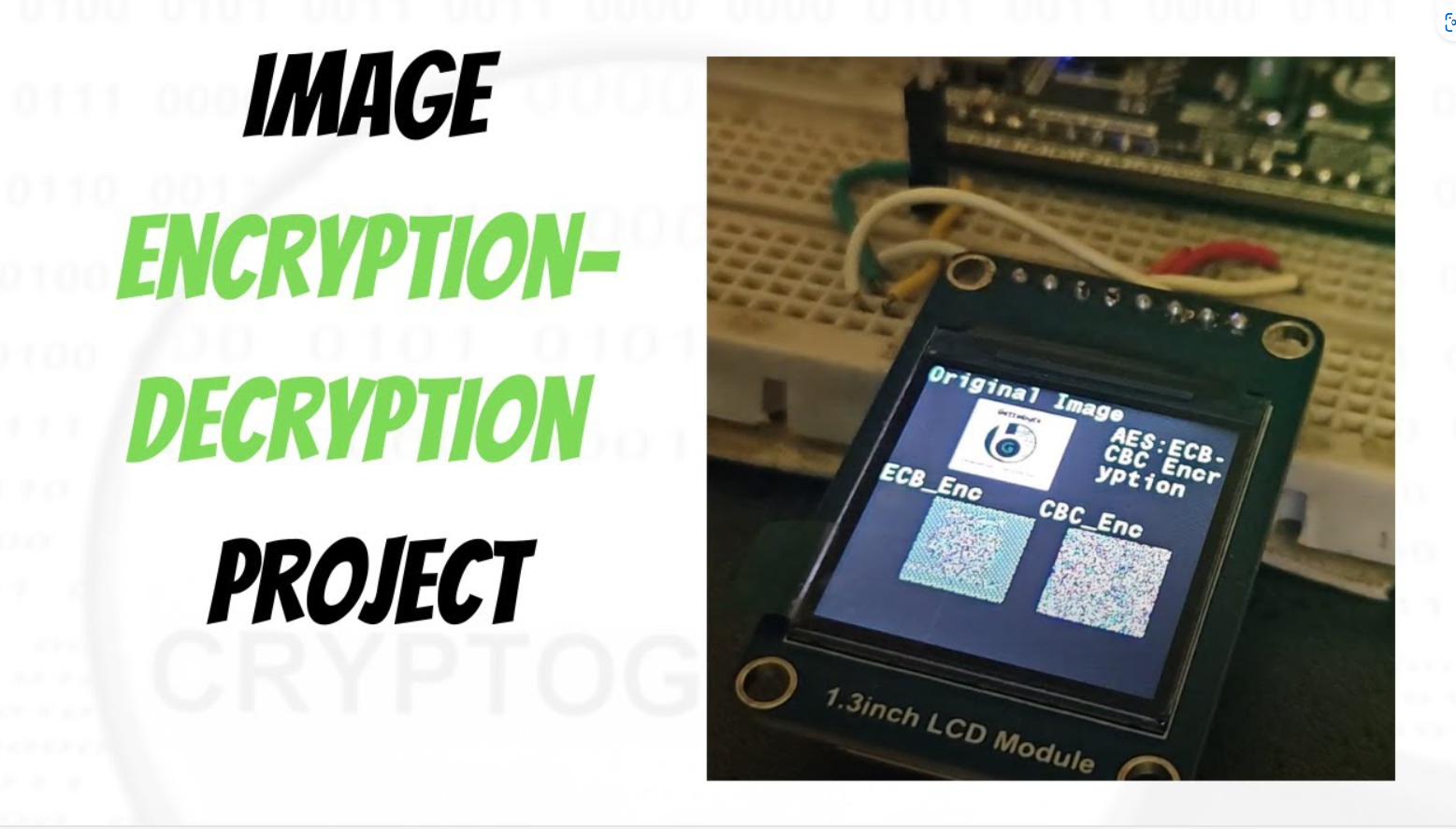

Learn Cryptography technology in embedded through DIY projects using NXP S32K144 Automotive Chips

Interfacing with the ElecronicsV2 Development Board