Introduction

–> SPI (Serial Peripheral Interface) is a popular way for devices like sensors, displays, and memory modules to talk to a microcontroller. If you’ve already read my blog about UART communication, you’ll remember that UART is great for simple, one-to-one communication. But SPI is the way to go when you need speed and want to connect multiple devices. Let’s break it down in a simple way!

–> As usual, while learning anything new, the initial questions are “What, Why, and How?“. Before jumping to these questions, there are important KEY ROLES in SPI to understand:

- Master: Controls the communication, generates the clock signal, and initiates data transfer.

- Slave: Responds to the master’s commands and communicates only when selected.

What is SPI?

–> SPI is a synchronous serial communication protocol that uses four main signals to transfer data:

- MOSI (Master Out Slave In): Data sent from the master to the slave.

- MISO (Master In Slave Out): Data sent from the slave to the master.

- SCLK (Serial Clock): A clock signal generated by the master to synchronize communication.

- SS (Slave Select): A signal to select the specific slave device (active low).

Why Use SPI?

- Fast: SPI beats protocols like I2C and UART when it comes to speed.

- Two-Way Communication(Full-Duplex Communication): You can send and receive data simultaneously.

- Straightforward: It’s pretty easy to set up and use in both hardware and software.

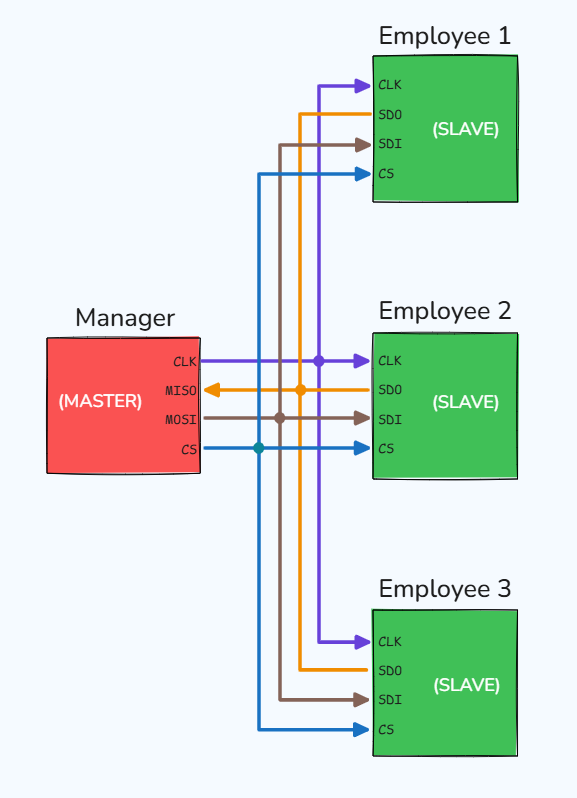

How SPI Works (Let’s Imagine a Manager and Employees)

Picture this: there’s a manager (the master) and three employees (the slaves) in an office. Each employee is responsible for specific tasks (different devices), but the manager only talks to one at a time.

Clock Synchronization (CLK): The manager ensures tasks are completed on time by setting strict deadlines (the clock signal). With each deadline, the manager assigns work to the right employee, ensuring everyone stays on schedule and performs their tasks at the right moment.

Data Exchange (MOSI & MISO): The manager assigns specific tasks (sends data via MOSI: Master Out Slave In) to the employee who can handle them. In return, the employee provides updates or results (sends data via MISO: Master In Slave Out) to the manager. This exchange happens systematically for the manager’s deadline (every clock pulse).

Slave Selection (CS): The manager chooses the right employee for the job by calling their name (activating their Chip Select (CS) line). While the chosen employee works, the others stay quiet, waiting for their turn.

–> So, with this teamwork, the manager keeps the tasks organized and ensures smooth communication.

SPI Modes (Clock Polarity and Phase)

–> SPI modes allow flexibility to adapt communication timing for different hardware designs. By defining the Clock Polarity (CPOL) and Clock Phase (CPHA),

Clock Polarity (CPOL): Determines whether the clock signal is idle at a low or high state.

- CPOL = 0: Clock is idle low.

- CPOL = 1: Clock is idle high.

Clock Phase (CPHA): Defines when data is sampled during the clock cycle.

- CPHA = 0: Data is sampled on the first clock edge.

- CPHA = 1: Data is sampled on the second clock edge.

–> The combination of CPOL and CPHA gives four modes:

- Mode 0: CPOL = 0, CPHA = 0

- Mode 1: CPOL = 0, CPHA = 1

- Mode 2: CPOL = 1, CPHA = 0

- Mode 3: CPOL = 1, CPHA = 1

–> These modes help avoid timing errors, ensure proper synchronization, and provide a standardized way to handle devices with different timing constraints. The four modes ensure efficient and reliable data exchange across diverse hardware.These modes help avoid timing errors, ensure proper synchronization, and provide a standardized way to handle devices with different timing constraints. The four modes ensure efficient and reliable data exchange across diverse hardware.

Example of an SPI Communication

–> This is an example of SPI communication where we sent a message “0x9F” through MASTER via MOSI pin and we get reverted with 3-byte data through the module as “0xEE, 0x00, and 0x30” via MISO pin. To understand this communication, after completion of this blog you can move towards this BLOG, where I have explained this SPI communication session.

Pros and Cons of SPI

–> Advantages:

- High-speed communication.

- Supports multiple slaves with individual SS lines.

- Simple hardware implementation.

–> Disadvantages:

- Requires more pins than I2C.

- No built-in error checking like CRC.

- Limited scalability for many slave devices due to SS pin usage.

Applications of SPI Communication

–> SPI is widely used in embedded systems and electronics for its speed and efficiency. Here are some common applications:

Sensors:

- SPI connects high-speed sensors like gyroscopes, accelerometers, and temperature sensors to microcontrollers.

Displays:

- OLED and LCD screens often use SPI for fast data transmission and real-time updates.

Memory Devices:

- External EEPROMs, Flash memory, and SD cards rely on SPI for reading/writing data at high speeds.

Communication Modules:

- Wireless modules like Bluetooth, Wi-Fi, and RF transceivers use SPI for control and data exchange.

Data Converters:

- ADCs (Analog-to-Digital Converters) and DACs (Digital-to-Analog Converters) frequently use SPI for transferring sampled data.

Motor Controllers:

- SPI is used to configure and communicate with motor drivers and controllers in robotics and automation systems.

Embedded Debugging:

- Debuggers use SPI for programming and debugging embedded devices.

–> SPI’s ability to connect multiple devices efficiently makes it a go-to protocol for applications demanding speed, precision, and real-time performance.