Motive

- To know about CAN peripheral in S32K144 Microcontroller, in terms of functional description and block diagram.

- To understand how FlexCAN peripheral works in NXP S32K144 MCU’s.( concept of message buffer, mailbox, fifo, meesage id table )(Done)

- To know how to use CAN peripheral by state machine diagrams. Picking different feature points and explaining their state machines.( Not Right now)

- To mention FlexCAN features and specs and giving just small brief.

To use CAN protocol in NXP Semiconductors S32K1xx Microcontroller’s, there is a peripheral present in S32K1xx series of MCU: The Flex CAN Module.

The FlexCAN module fully implements the CAN protocol specification, including the CAN with Flexible Data rate (CAN FD) protocol and the CAN 2.0 version B protocol. It supports both standard and extended message frames, as well as long payloads upto 64 bytes in the case of CAN FD.

FlexCAN Module is a peripheral in NXP S32K series of Microcontrollers. All NXP S32K1 and S32K3 microcontrollers have same module FlexCAN which is to be used for doing CAN communication via these microcontrollers. FlexCAN is IP of NXP Semiconductors, that is used in their Automotive Microcontrollers as a microcontroller peripheral which is used for CAN communication. NXP S32K1xx and S32K3xx series of microcontrollers are used in making car ECU’s. In car ECU’s we often have to do the CAN communication for data transfer between 2 ECU nodes. In those cases FlexCAN module is used to do communication via CAN protocol.

To know about how CAN communication is done via microcontrollers will recommend reading previous blog: CAN protocol in embedded.

What is FlexCAN Module

FlexCAN Module is a Microcontroller peripheral in NXP Semiconductors S32 series of microcontroller for doing CAN communication via CAN protocol. S32 series have number of microcontrollers, for understanding we are going to refer S32K144 microcontroller, as this blog series is specific to S32K144 MCU.

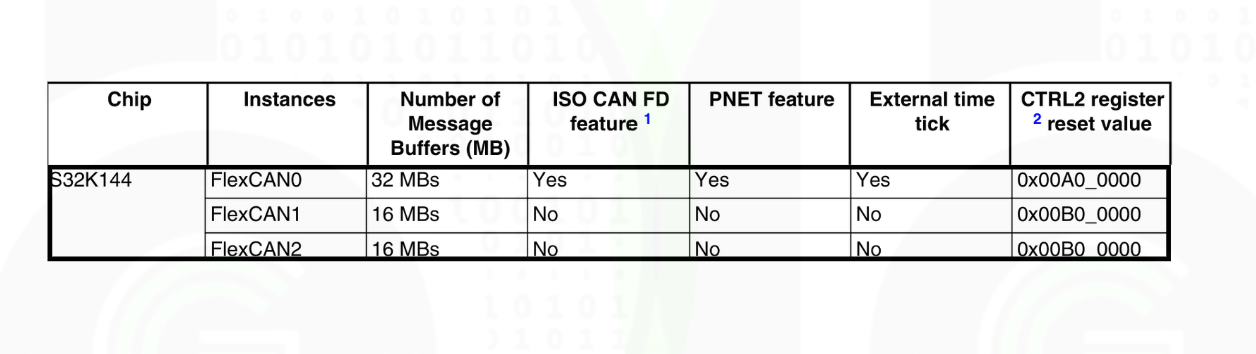

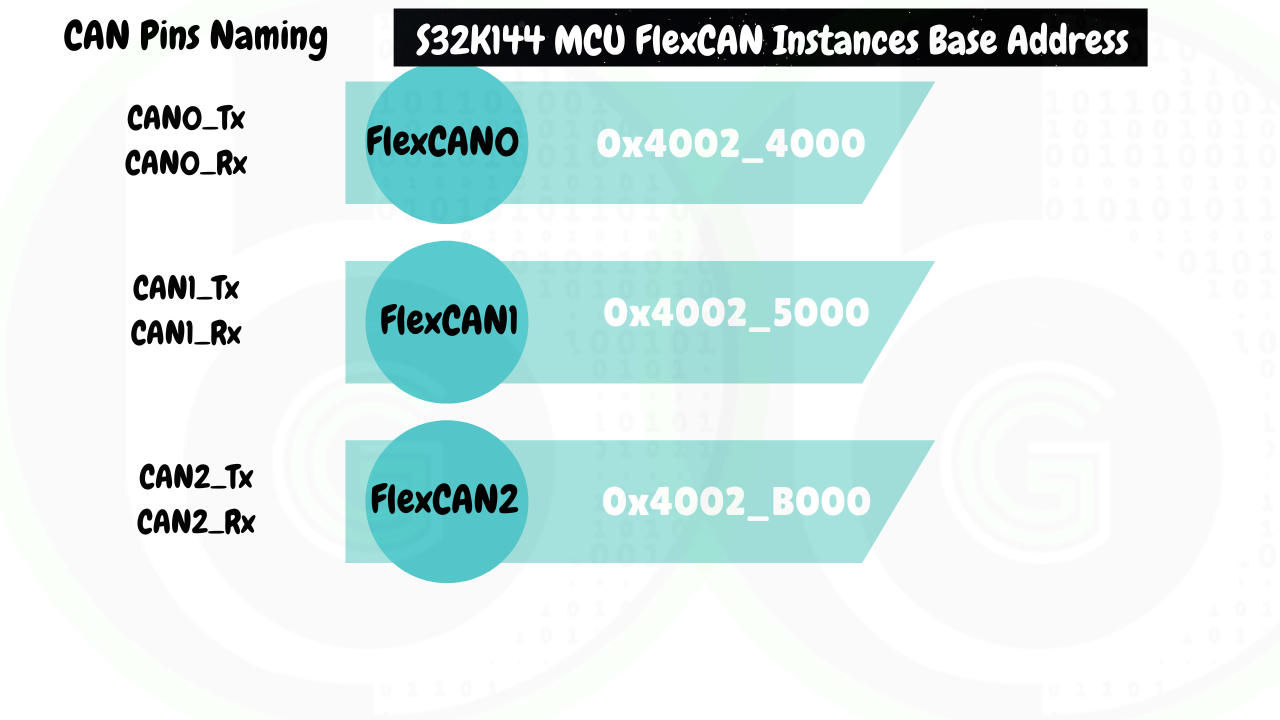

There can be multiple instances of FlexCAN module in a microcontroller. Like in S32K144 MCU it has 3 instances of FlexCAN module, whereas in S32K344 has 5 instances of FlexCAN module. By instance we mean, number of counts. So, in S32K144 we have 3 FlexCAN modules, meaning 3 communication channels of CAN be done via S32K144. In S32K344 we have 5 FlexCAN modules, meaning 5 communication channels can be done via S32K344.

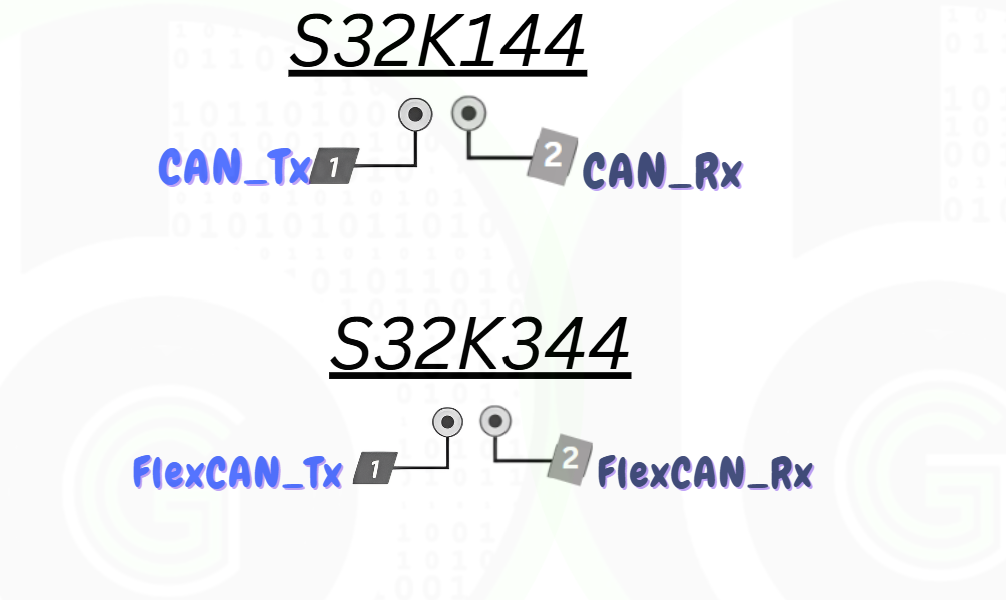

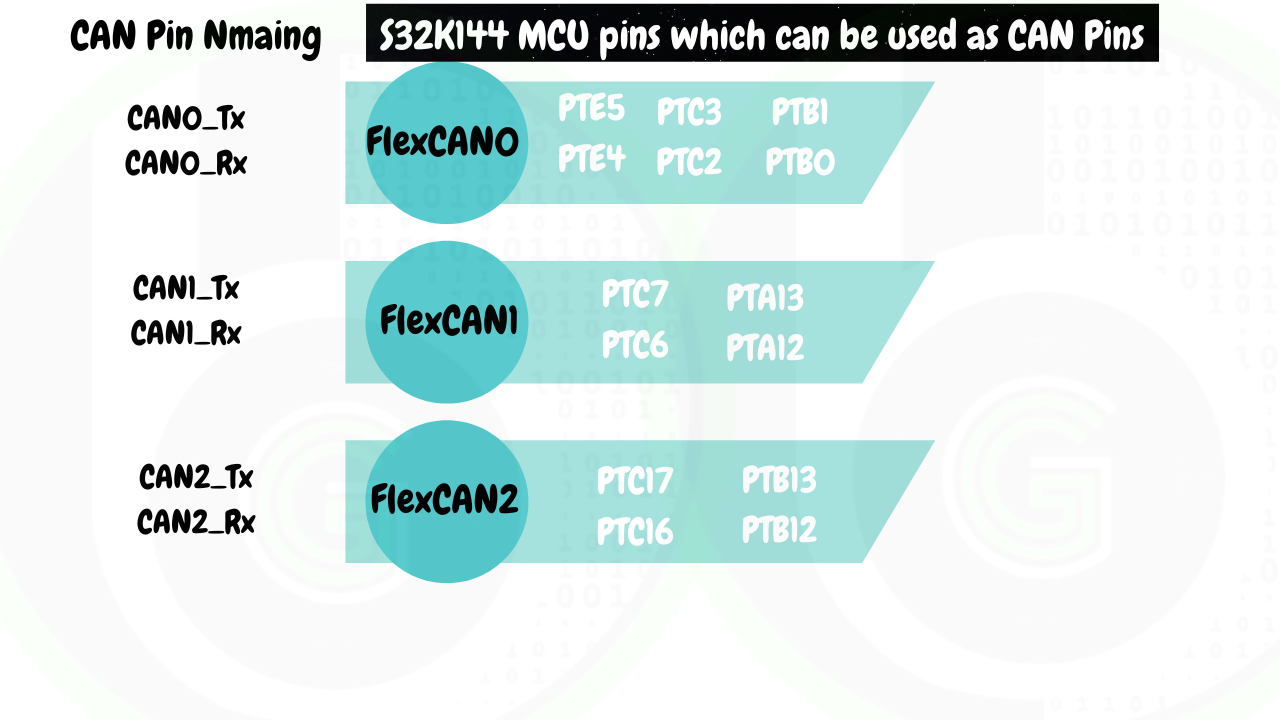

Now for doing CAN communication, FlexCAN module would be using CAN pins of the microcontroller to physically transmit and receive CAN data. The CAN pins are termed as CAN_Rx-CAN_Tx pins in the case of S32K144 MCU and FlexCAN_Tx-FlexCAN_Rx in the case of S32K344 MCU. CAN_Rx & FlexCAN_Rx for receiving pins and CAN_Tx & FlexCAN_Tx for transmitting pins.

Each FlexCAN instance in a microcontroller might have different features. Like in S32K144, FlexCAN module 0 has 32 Message buffers, while FlexCAN module 1 and 2 have 32 message buffers.

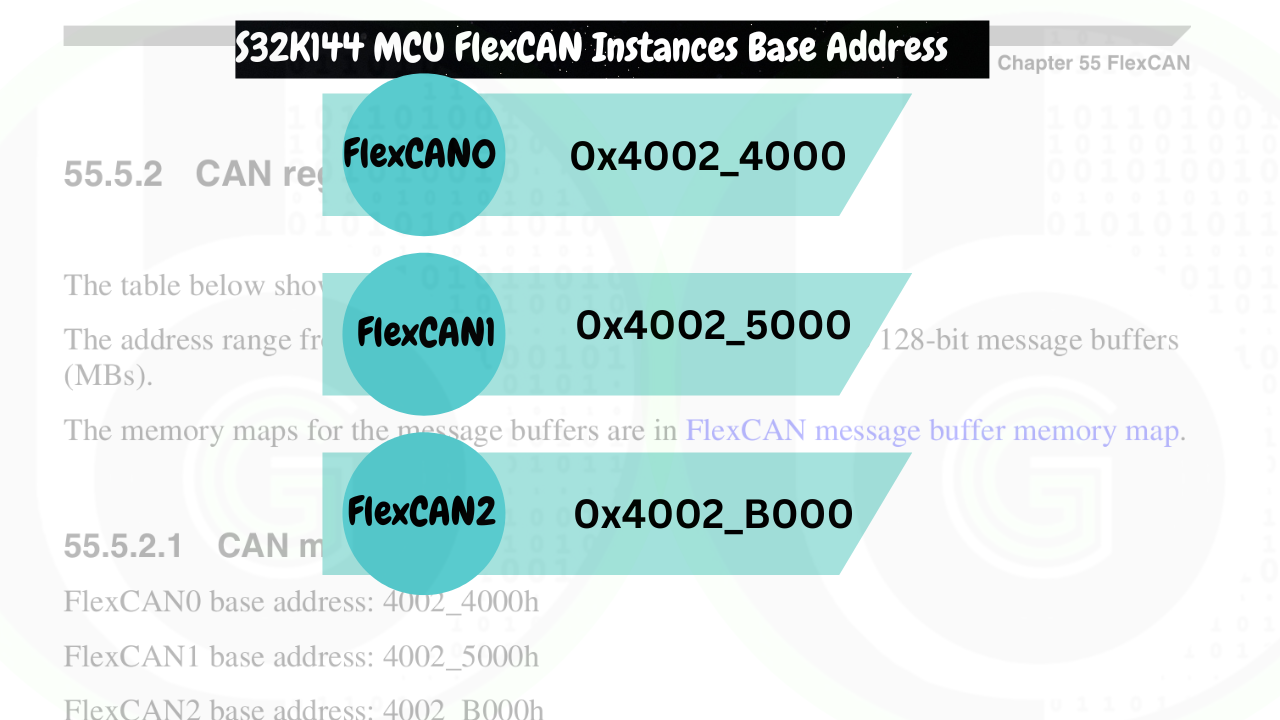

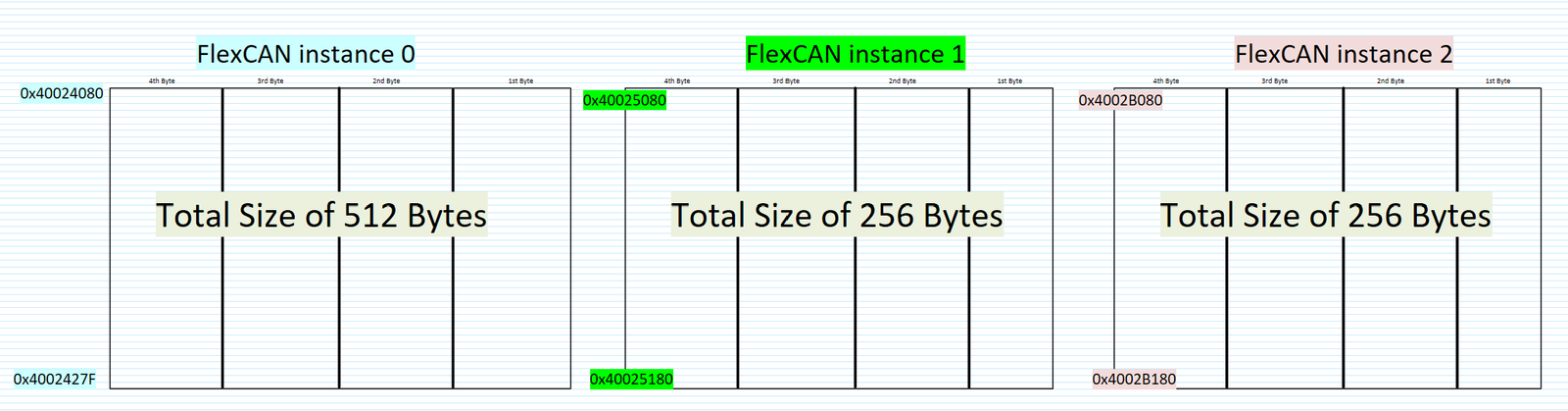

Each Instance of FlexCAN has their own FlexCAN peripheral registers. Which starts at mentioned address of microcontroller memory. These address are named as FlexCAN instance base address.

Now which pin to use via which instance is logically mapped as per numbering. FlexCAN0 would be using CAN0_Tx and CAN0_Rx pins. FlexCAN1 would be using CAN1_Tx and CAN1_Rx pins and so on.

Now further for each CAN instance there are number of pins available. Meaning let’s say we want to use FlexCAN module0 of S32K144 MCU. For that we will be using CAN0_Tx and CAN0_Rx pins. CAN0_Tx and CAN0_Rx pins can be mapped to number of pins of microcontroller. As shown in Figure

We have to set the alternate function registers of the microcontroller to configure the pin that we want to use for corresponding Instance. This pin configuration part is handled by Port Peripheral of the S32K144 Microcontroller.

For setting the speed of communication of FlexCAN module, we have to configure its clock and baurate settings. The Clock to FlexCAN module is fed from Clock peripheral of MCU and then FlexCAN module baudrate can be set by application as per their requirements.

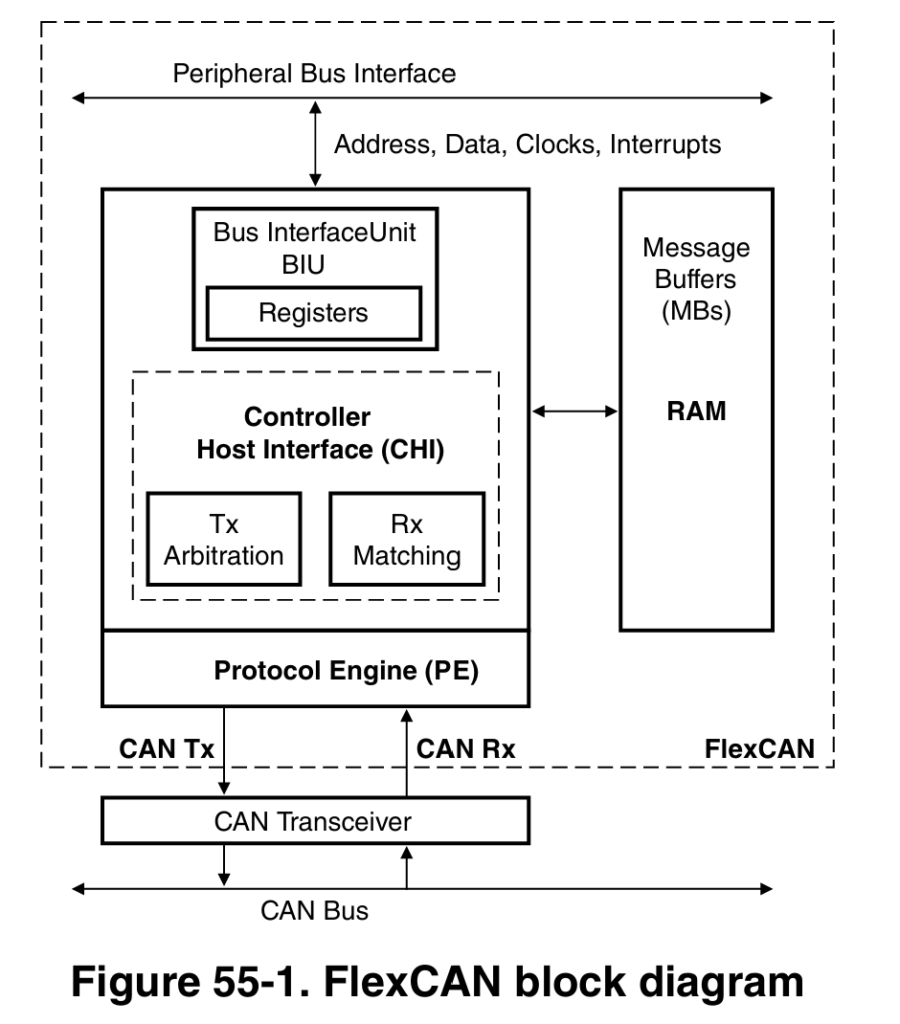

Block Diagram of FlexCAN Module

FlexCAN peripheral block diagram understanding

CAN Protocol Hands-on Course with CAN analyzer

Working of FlexCAN Module

- FlexCAN module implements the CAN protocol according to the ISO 11898-1 standard and CAN2.0B protocol specifications.

CAN 2.0B protocol specification defines the properties and features in CAN protocol (Standard CAN and Extended CAN) and ISO-11898-1 standard specifies how outgoing and incoming CAN data should be managed so that CAN properties are achieved.

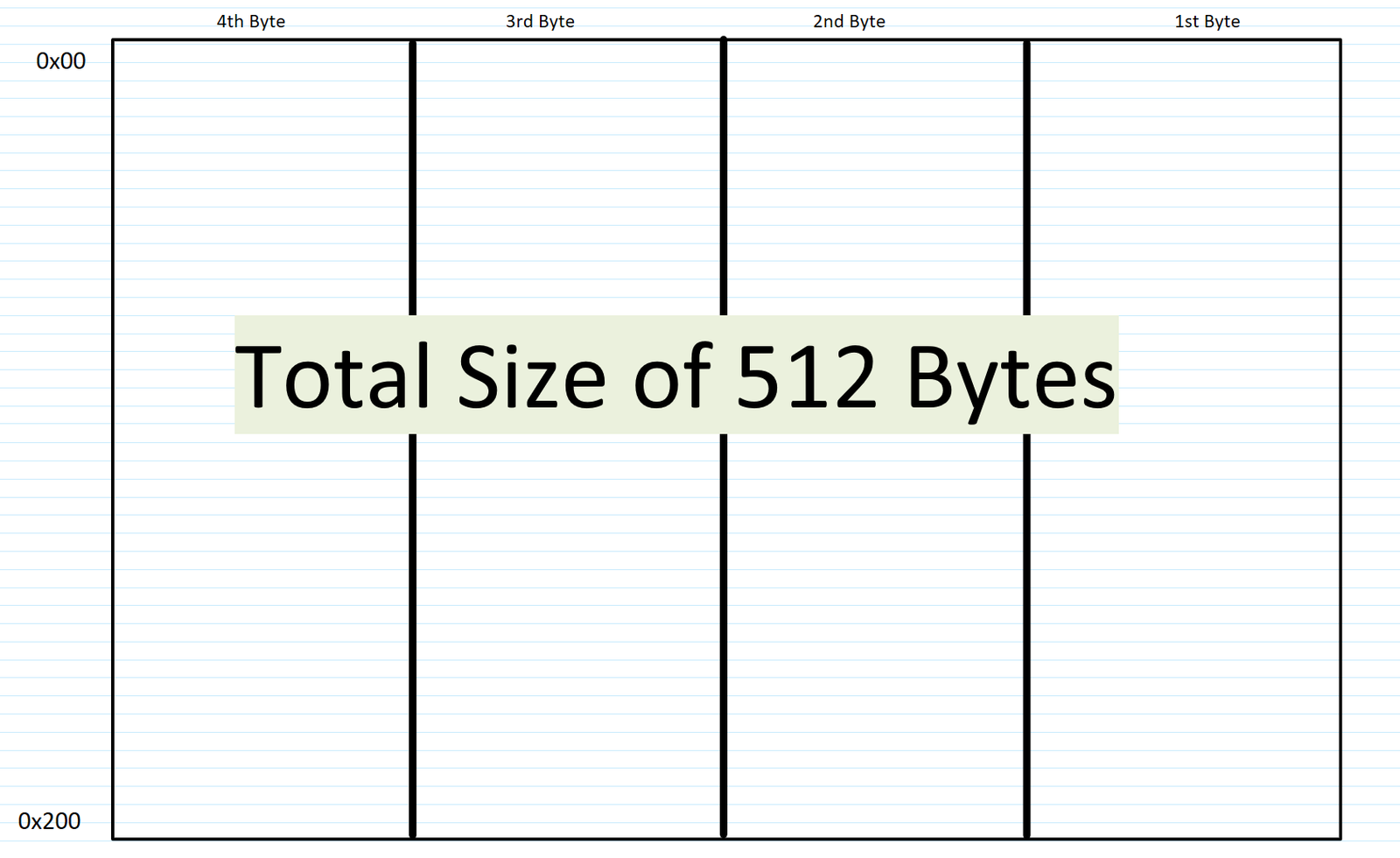

- In FlexCAN module, message buffer space is being termed as Embedded RAM. Both Terms would be used interchangeably throughout the blog.

- FlexCAN peripheral has a fixed Embedded RAM Space which is used to process the CAN data. In S32K1xx Microcontroller’s, the Embedded RAM is of 512 bytes.( Explain for chapter of can peripheral register where address range of message buffer is specified)

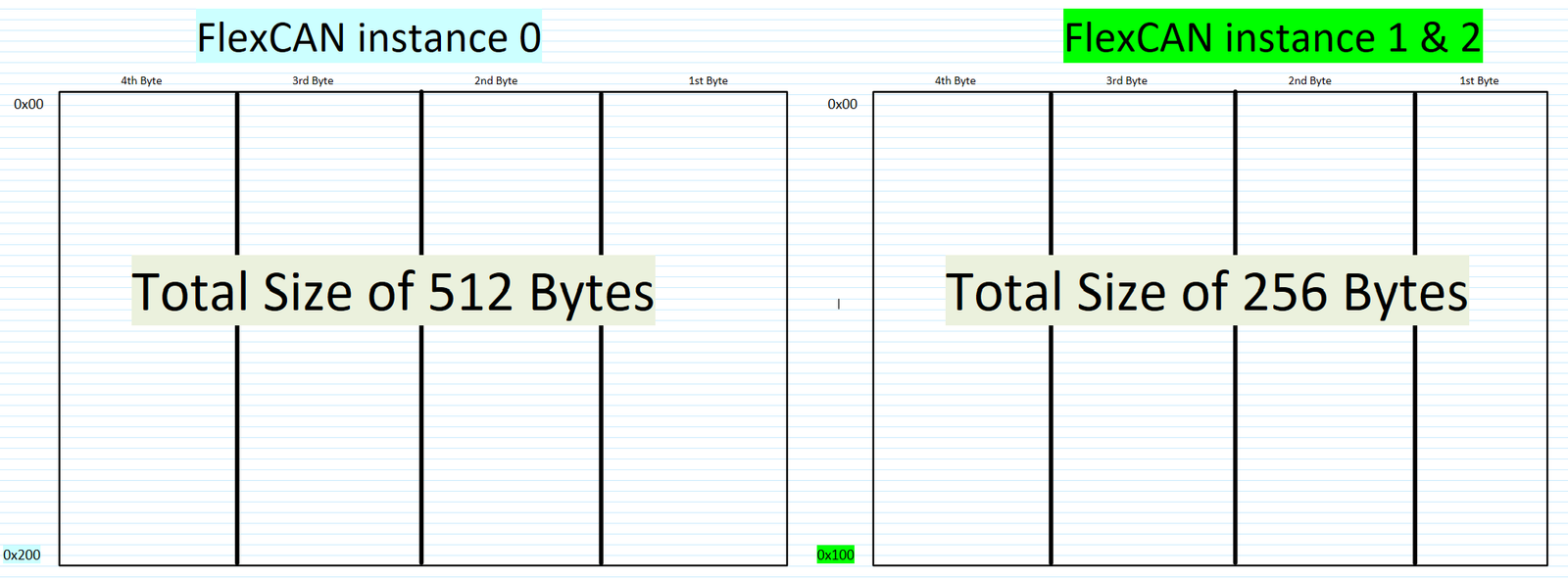

- Each FlexCAN instance in S32K144 MCU has their own Message buffer, but they are of different sizes.( explain from instance feature difference table and then comparing that to above point statement)

FlexCAN instance 0 has 512 bytes and FlexCAN instance 1&2 has 256 bytes of Embedded RAM.

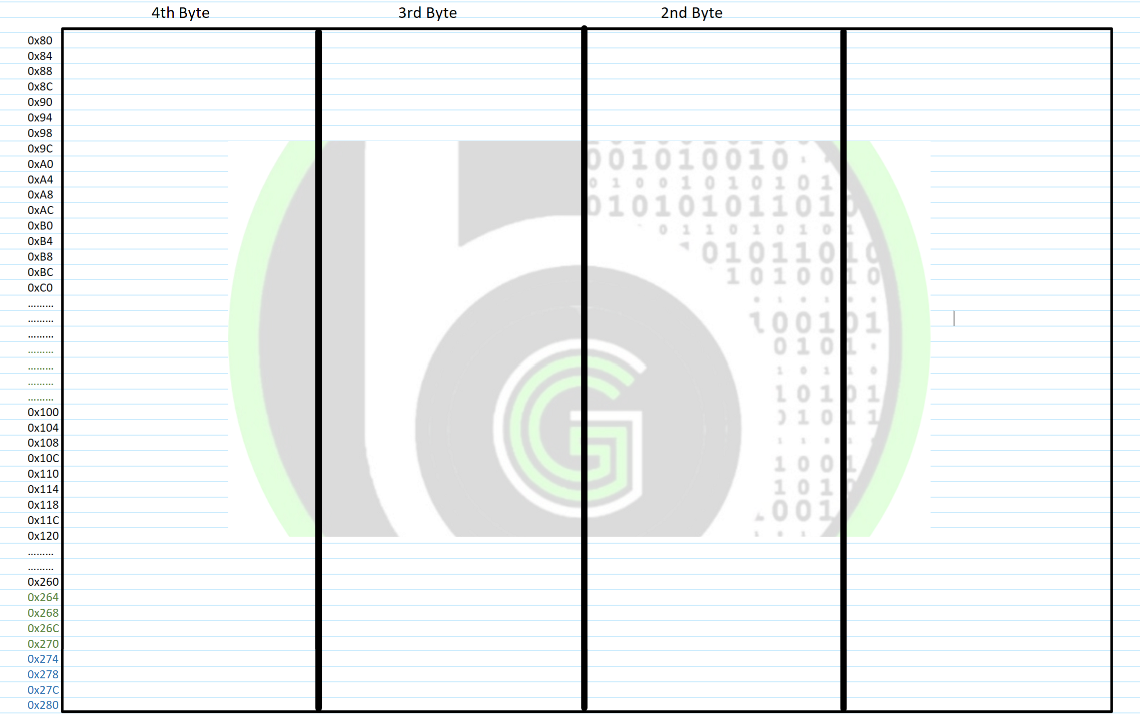

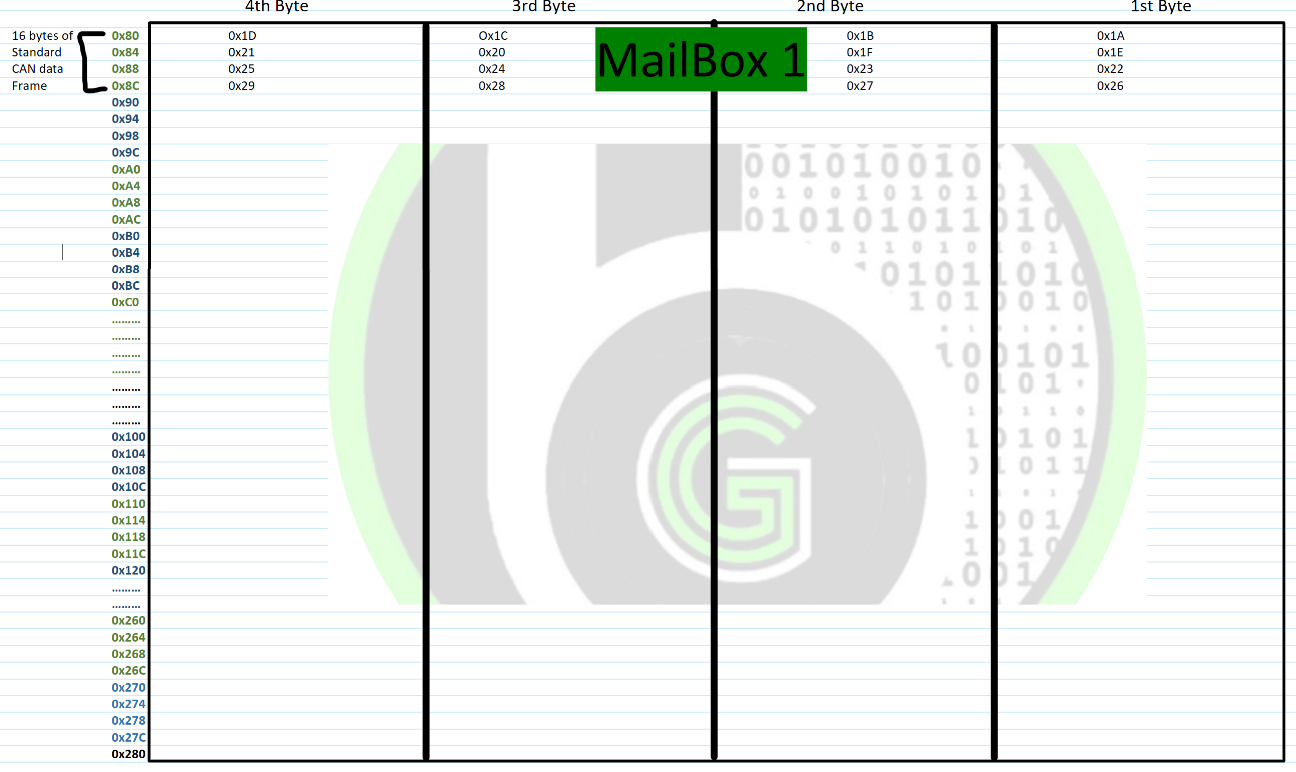

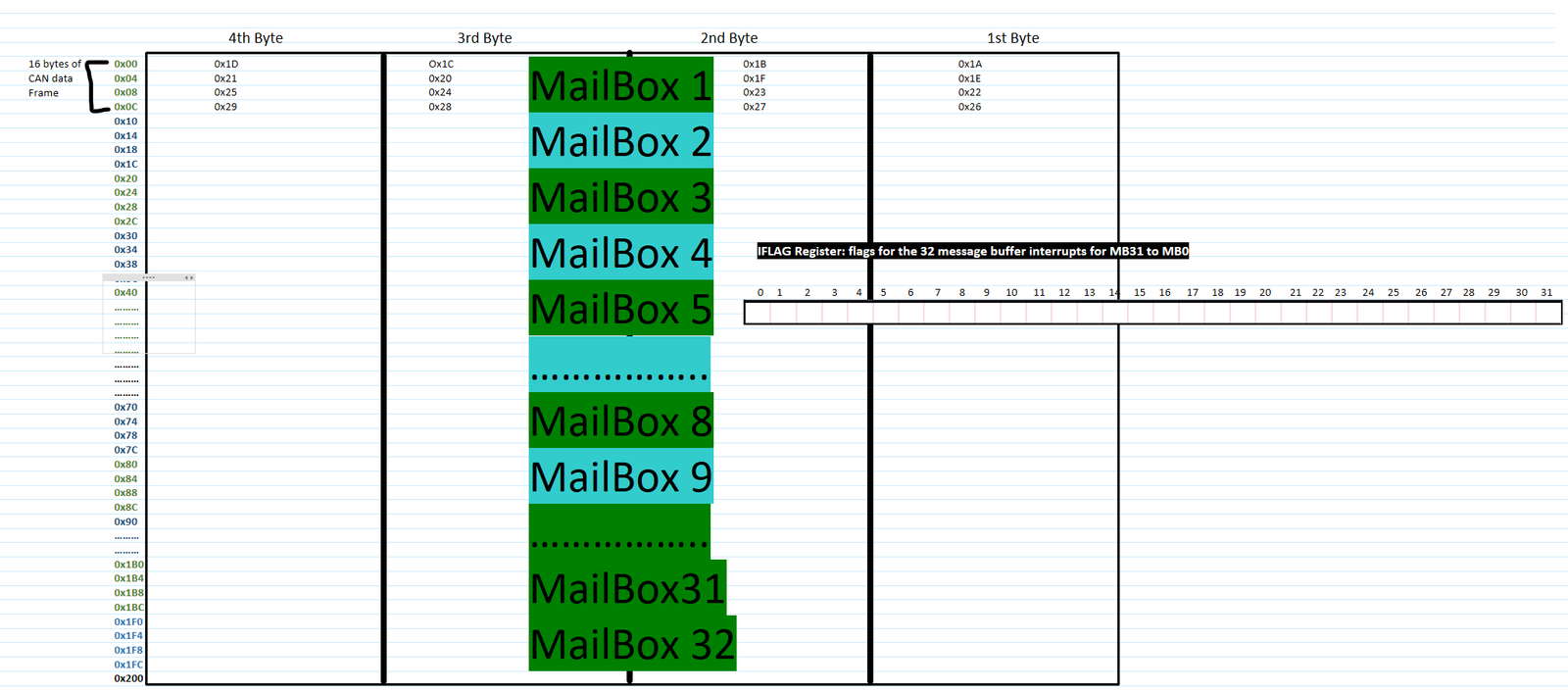

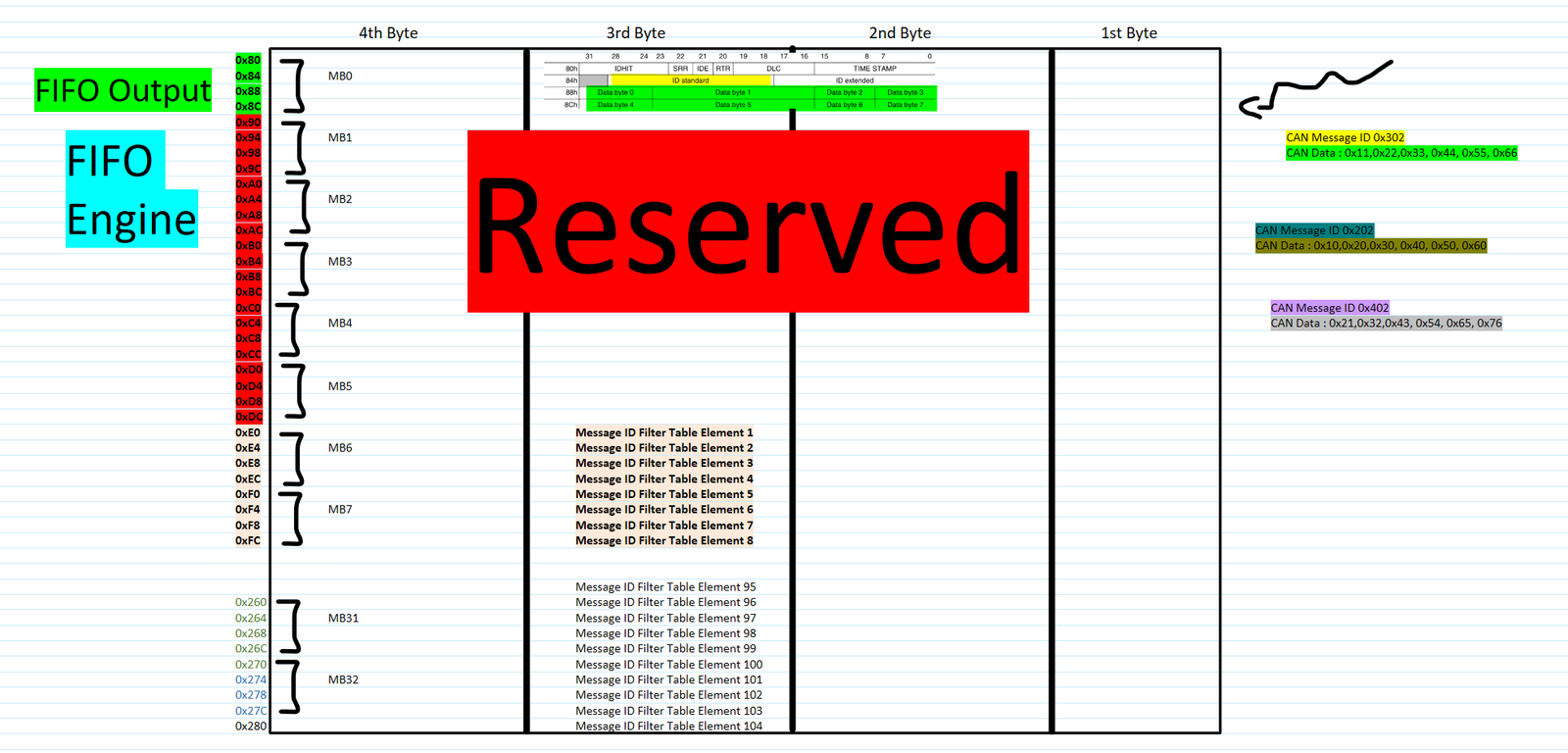

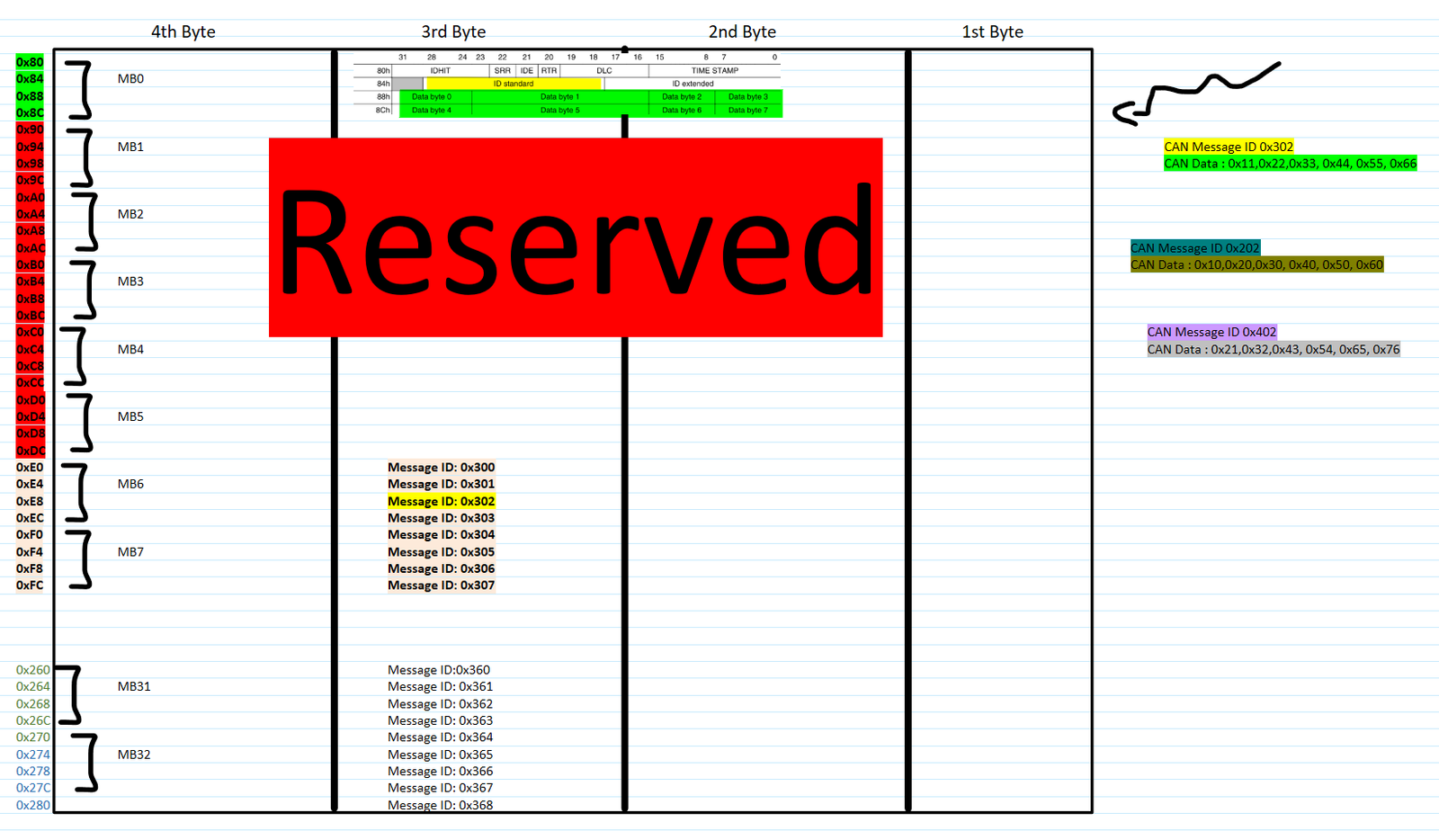

- The Embedded RAM in FlexCAN Peripheral space starts from address of 0x0080 offset of corresponding FlexCAN instance base address. Embedded RAM space is from 0x080-0x280 memory address in case of FlexCAN module 0 and from 0x080-0x180 in case of FlexCAN module 1&2.

For FlexCAN Instance 0 message buffer starts at: 0x40024080, FlexCAN instance 1 message buffer starts at 0x40025080 and for FlexCAN instance 2 message buffer starts at 0x4002B080

- Now if we zoom in to Embedded RAM space, its is divided by offset of 4 bytes. As Shown in figure.

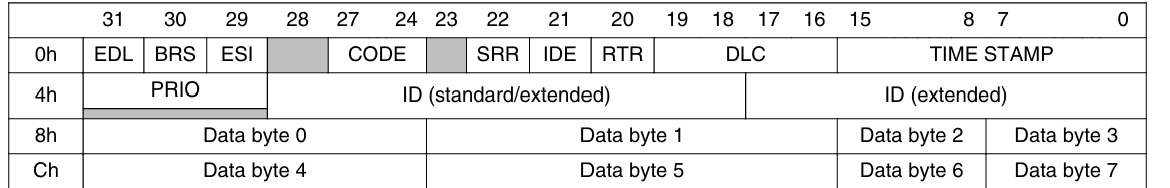

- Further, if we zoom in to write/read on Embedded RAM it has a structure, according to which CAN data frame is written/read into it. It is called Message Buffer Structure. We will get into it in message buffer structure section.

MailBox Mechanism

- If we have Standard CAN frame, in which we are sending 8 bytes of payload data, so according to above message structure it is gonna occupy 16 bytes of space. Starting from first address pace of message buffer: 0x80 till 0x90, first 4 rows would be occupied to write a single CAN data frame. Whether its a Standard CAN frame or Extended CAN frame, its gonna be occupy 16 bytes only.

- If we are using CAN FD, in which we are sending 16 bytes of payload data, so according to above message structure it is gonna occupy 24 bytes of space. Starting from first address pace of message buffer: 0x80 till 0x98, first 6 rows would be occupied to write a single CAN data frame of CAN FD.

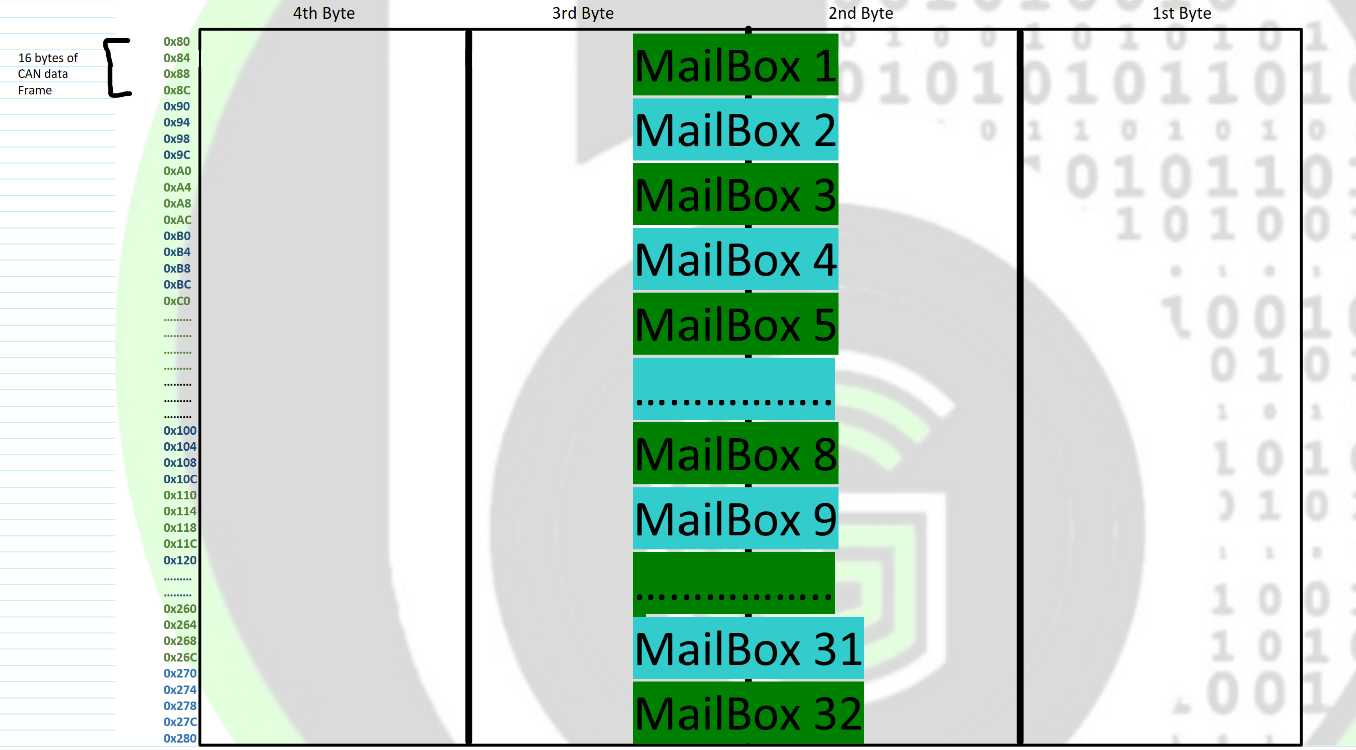

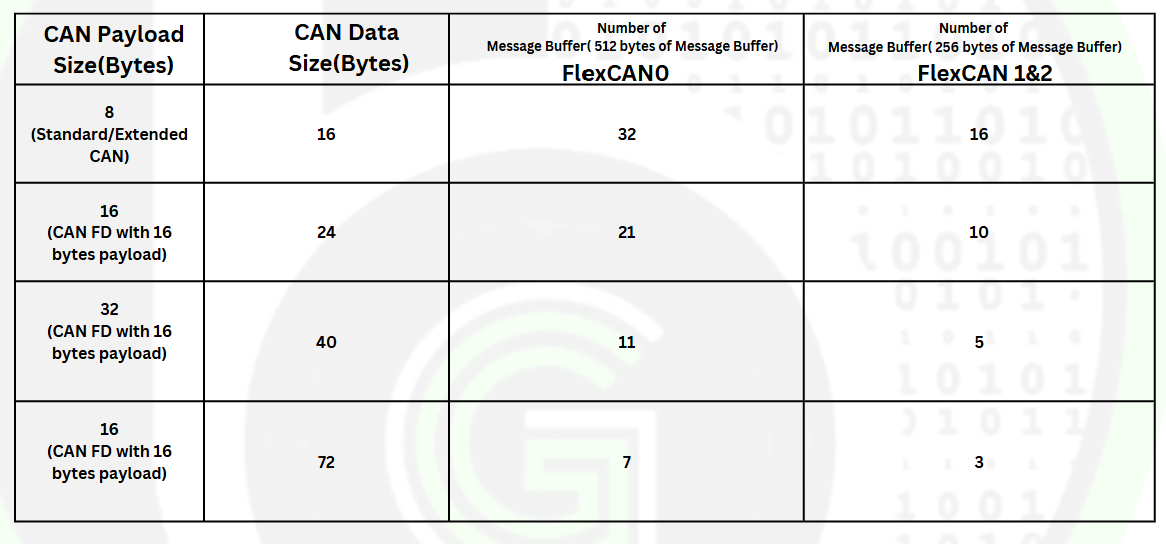

- In the case of 512 bytes of Embedded RAM and CAN data size of 16 bytes, we can have total 32 such sections of Embedded RAM. Each Section is termed as mailbox,

- Each Mailbox can be configured as reception or transmission, all supporting standard and extended messages.

- Number of mailboxes would be different. It would not be 32 everytime. FlexCAN module have flexible mailbox configuration according to CAN data size and instance of FlexCAN that we are using:

- So, in Extended and Standard CAN communication, a single CAN Data Frame will be of 16 bytes. But in the case of CAN-FD a single CAN Data frame can be of 16,24,40 or 72 bytes depending on message payload of 8,16,32 and 64 data bytes. So according to message buffer structure(As Data payload will increase) more memory space of Embedded RAM would be consumed for writing single CAN data frame of higher payloads and so does our total mailbox count will decrease.

- Also in FlexCAN instance 0, it has message buffer space of 512 bytes so it can fit in 32 mailboxes of 16 bytes CAN frame. In the case of FlexCAN instance 1 & 2, it has message buffer space of 256 bytes so it can fit in only 16 mailboxes. So, mailbox count also varies depending on size of message buffer space.

- Now for better understanding we are going to refer FlexCAN instance 0 and Standard CAN, which occupies 16 bytes of CAN single frame.

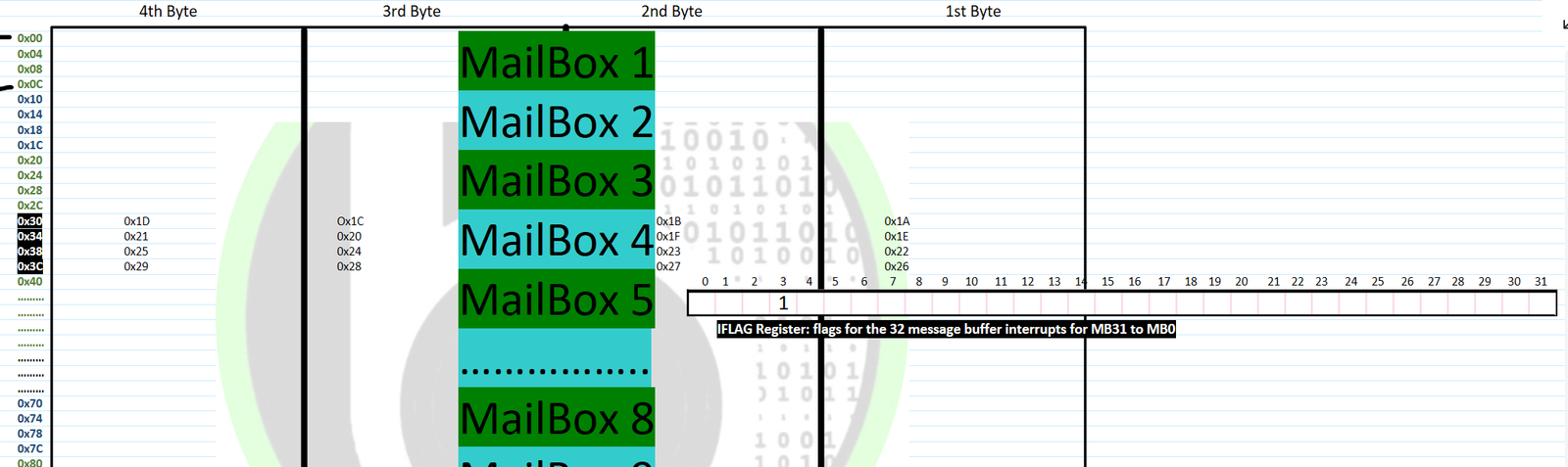

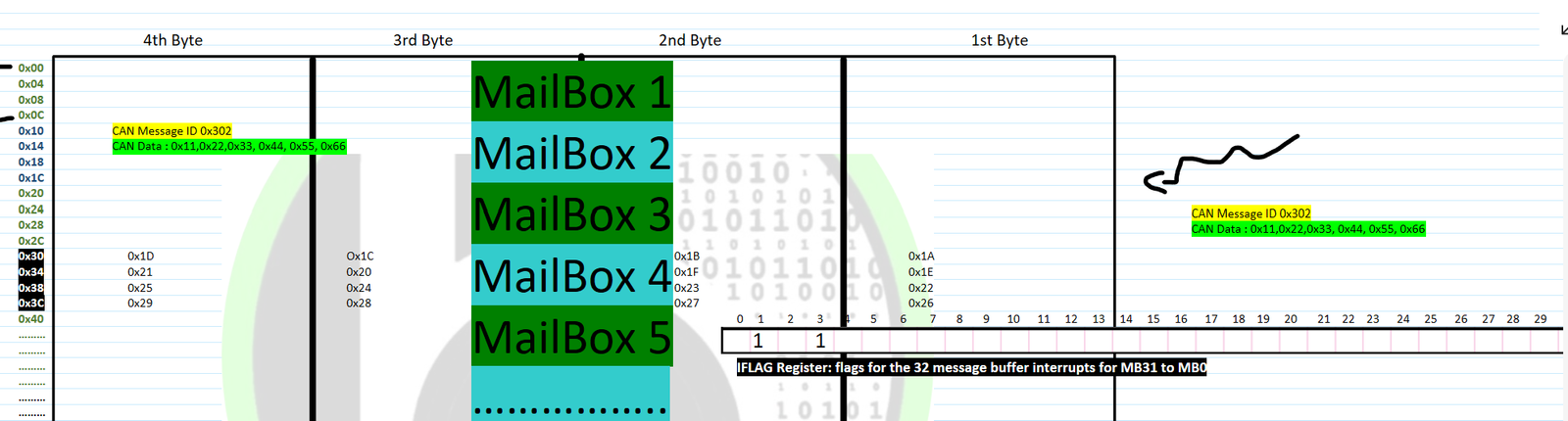

- Then as CAN message ID and data is written into address denoted my that mailbox number, a Flag will be set in IFLAG1 FlexCAN peripheral register signifying successful transmission/reception of CAN frame.

- IFLAG1 register is interrupt status register, which has 32-bit fields. Each bit for one mailbox. So corresponding bits of IFLAG register will be set depending upon mailbox used.

- So if say mailbox 4 is used for transmission of CAN data, in which 0x320 message ID and CAN data of : 0x11, 0x22,0x33 and…. is written. So IFLAG1[4] bit will be set, when Successful CAN transmission is done. Now as mailbox 4 denotes address xyz in case of flexcan_instance 0. So we need to fill corresponding message buffer address space with corresponding contents as per message buffer structure at xyz address. In this case MCU will write CAN message ID and CAN data on the mailbox address space.

- And say if mailbox 2 is used for reception, which we(MCU) will configure with message ID 0x302. meaning if any CAN message is received by CAN peripheral with message ID 0x300, it will copy its data into the address of mailbox 2. MCU will read the CAN data from this address and on successful reading/receiving IFLAG register bit will be set. The corresponding bit of IFLAG will be set depending on mailbox value.

FIFO Mechanism working

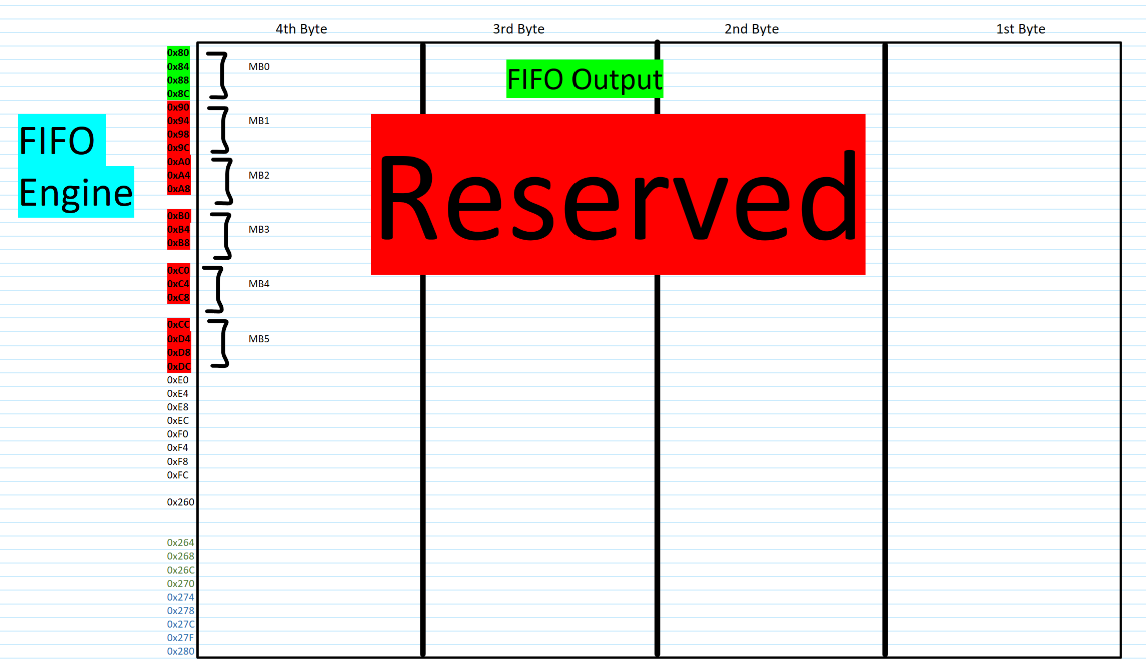

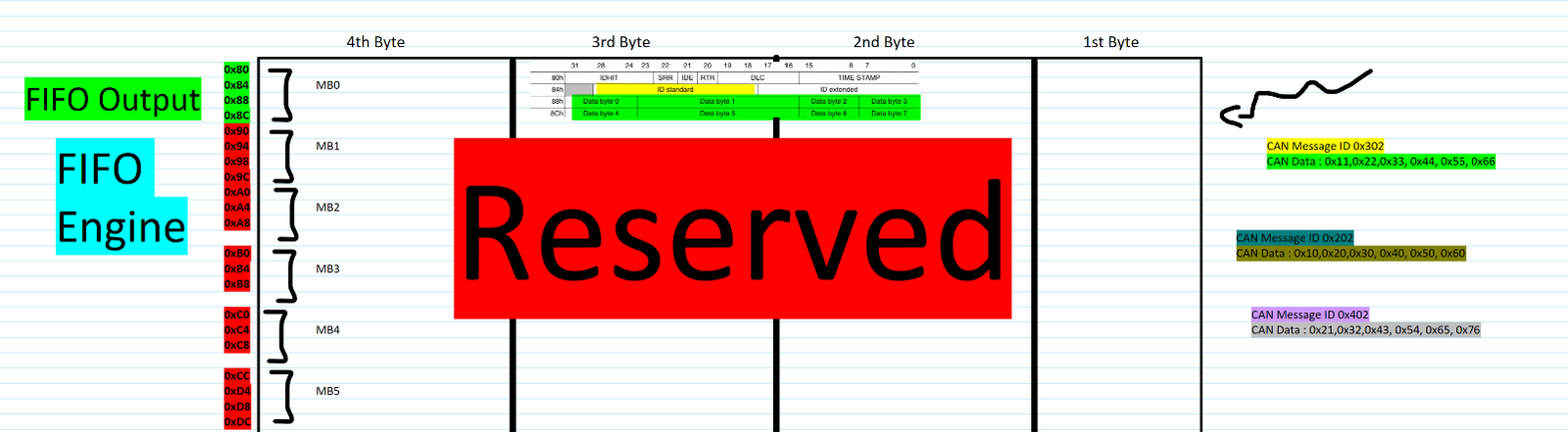

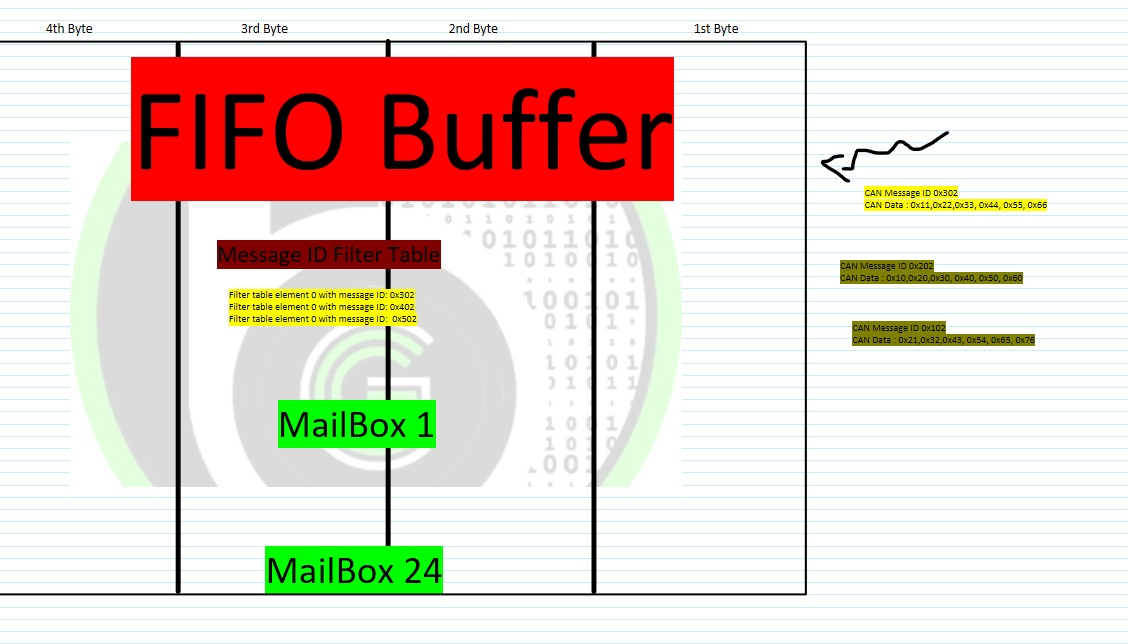

- When we are using FiFo configuration in FlexCAN module, address space 0x80-0xDC of message buffer would be occupied by FiFo Buffer.

- The reserved area is used for internal use for doing FIFO mechanism and FIFO output/buffer will store the received CAN frame, according to Rx FIFO structure which must be read by CPU as a message buffer.

- Now FIFO output is buffer, in which external CAN message Data will be received only if it matches the acceptance criteria in Message ID filter table. Acceptance criteria is based on message ID. If External CAN message ID matches with Message ID mentioned in Message ID filter table, only then FIFO buffer will be filled with corresponding CAN message data.

- Now this Message ID filter table is also in message buffer address space only. When FIFO mechanism is enabled, address space from 0xE0 to 0x280 can be used by message ID filter table, in the offset of 4 bytes. In every Message ID filter table element, we can configure which message ID to be accepted.

- This configuration is based on Message ID table structure. More the number of filter elements, a greater number of different CAN messages based on their message ID can be configured to get accepted and received.

- One interesting here to observe is that for doing FIFO mechanism, mailboxes 0-5 are consumed by FIFO engine. And by default, mailboxes 6-7 are used by Message ID filter table. So if we are using FIFO mechanism, number of mailboxes available to us will be decreased.

- Then in order to use mailboxes, we will be able to use number of available mailboxes left after FiFo Consumption. So saw we want to use mailbox 4 further for transmission of CAN data, if FIFO mechanism is being enabled. Then it would show an error, one of the error status bit would be set. As mailbox 4 memory location is being used by FIFO engine. If we use mailbox 9, we can use that as FIFO engine ends at mailbox 5 and Message ID Filter table elements ends at mailbox 7 by default. So when using FIFO for receiving the CAN data, then in that case for transmission we have to make sure that mailbox number which we use is apart from mailboxes which are consumed in FIFO engine and message ID filter table elements.

- Also their are many features in FlexCAN module via which priority of messages to be send with Mailbox can be used. We will be covering those things as we cover the practical experiements.

In the case CANFD, FIFO mechanism cant be used. For CAN FD, we have to use mailbox mechanism only for transmiting and receiving the messages.

For now we have got to know the basic working and understanding of how FlexCAN module works. Now we are going to do some handson demo projects for understanding how CAN communication is done using MailBox and RxFiFo mechansims in FlexCAN mdoule.

Their are many advance and intermeditae features too in FlexCAN like Pretended Networking Mode, differer power modes, TimeStamp and filtering mechanisms. We will cover some of the topics in upocoming courses and blogs and some of the topics are subject to explore by yourself. But in things, the basic foundation is going to be the working which we have gone through above.

CAN Protocol Hands-on Course with CAN analyzer

Functional Description

Clocks

Transmit Process

Explain a bit about Arbitration process

Receive Process

filtering mechansim

Interrupt, DMA and Polling

FlexCAN Advance and extra Features

- Low-Power Modes

- Modes of Operation

- CAN FD

- Timestamp

- Transceiver Delay Compensation

- Tx Arbitration Start Delay

Conclusion

So that all for this blog, we have got overview and understanding of working of FlexCAN peripheral in NXP S32 Automotive Microcontrollers.

Now from next blog, we will dive into using the FlexCAN peripheral for doing CAN communication via NXP S32K automotive controllers. To use the FlexCAN peripheral, we have to use microcontroller software stack. And we have 2 options for that:

- Autosar MCAL layer standard based RTD

- Non Autosar MCAL Layer standard based RTD.

At first, we are going to explore non-Autosaur MCAL layer standard based RTD. After that we will move to Autosar MCAL layer Standard based RTD.