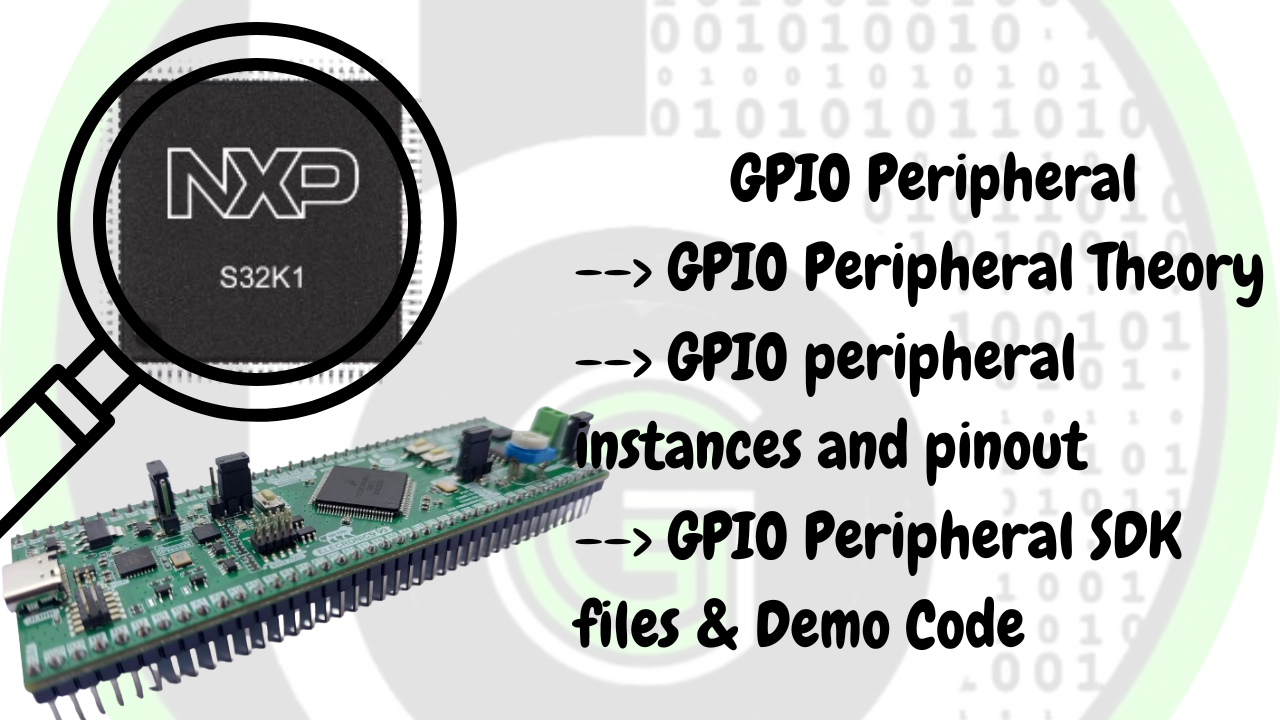

What is GPIO peripheral in NXP S32K1xx MCU || Briefing about how to use GPIO peripheral in NXP S32K1xx MCU’s

Decoding the working of MFRC522 RFID Receivers to interface them with Host MCU/MPU

So, hello to all viewers and welcome back to Gettobyte Platform. In This blog you are going to know about

Table of Contents What is RFID technology? RFID is a technology by which objects can be tracked and identified using

In the last blog I talked about the basics of MPU6050, this time let’s see how to interface it with

Most of us are fans of Video Games. We played a lot of games on our mobiles like PUBG, Call

What is PWM? PWM or Pulse Width Modulation, is a type of digital electrical signal which is periodic in nature,

Learn about basics of cryptography technology for embedded world